To safely disconnect a transport dolly from a Rotochopper Generation II transport dolly, start by parking on level ground and […]

Learn MoreHow to Connect & Disconnect a Rotochopper Generation II Transport Dolly from a Tow Vehicle

This Rotochopper University Instruction Guide outlines the steps for connecting and disconnecting a transport dolly from a tow vehicle. […]

Learn MoreRotochopper Welcomes Mike Elling as Chief Financial Officer

We are delighted to announce the addition of Mike Elling to the Rotochopper team as Chief Financial Officer (CFO). In […]

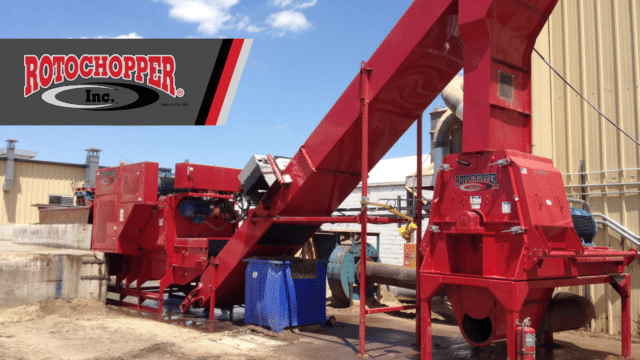

Learn MoreHow The Rotochopper RMT Hammermill Opens New Market Opportunities

In an era where innovation intersects with sustainability, Rotochopper is revolutionizing the way industries approach waste management and recycling. In keeping […]

Learn MoreHow to Connect a Rotochopper Horizontal Grinder to a Generation II Transport Dolly

This Rotochopper University Instruction Guide outlines the steps for connecting a grinder to a transport dolly efficiently. It begins […]

Learn MoreRotochopper University 2024 Equips Operators for Success

Rotochopper, a leading manufacturer of horizontal grinders, shredders, and screening equipment, successfully concluded its annual Rotochopper University training program in […]

Learn MoreWhen to Retire Your Horizontal Grinding Equipment

Horizontal grinding equipment is built to weather the demands of industries ranging from organic waste recycling and pallet demolition to […]

Learn MoreHow to Keep On-Site Grinder Operators Safe

Industrial horizontal grinders, while critical to the smooth operation of many waste reduction worksites, can pose a possible hazard to […]

Learn MoreIntroducing Sarlac: Your Compact and Economical Solution for Material Downsizing and Recycling

St. Martin, MN – Rotochopper, Inc. proudly announces the launch of Sarlac, a cutting-edge machine designed to revolutionize material downsizing […]

Learn More2023 Year in Review

As 2023 draws to a close, we reflect on its challenges and triumphs. We extend heartfelt gratitude to our customers, […]

Learn MoreHorizontal Grinder Screen Types: An Overview

A successful operation relies just as much on its equipment as it does its people, and grinder screens are among […]

Learn MoreC&D Waste Management Company Transitions to Green Waste Recycling with Rotochopper

Background Bee Green Recycling & Supply is a green waste recycling company based in Oakland, California. Founded in 2009 by […]

Learn MoreRotochopper, Inc.

217 West Street, PO Box 295

St. Martin, MN 56376

Phone: 320-875-9950

Email: info@rotochopper.com

Stay Connected

Connect with Rotochopper to see our machines in action, new products, news and events!

Join our Email List to stay up to date on the latest product releases and updates, industry news, and offers.

We would love to see your photos and videos! Tag #Rotochopper in your posts to share them with us.