We specialize in grinding, shredding, screening, and supporting equipment that transforms waste materials into profitable opportunities like colored landscape mulch, animal bedding, biomass fuels, and compost.

Rotochopper Equipment

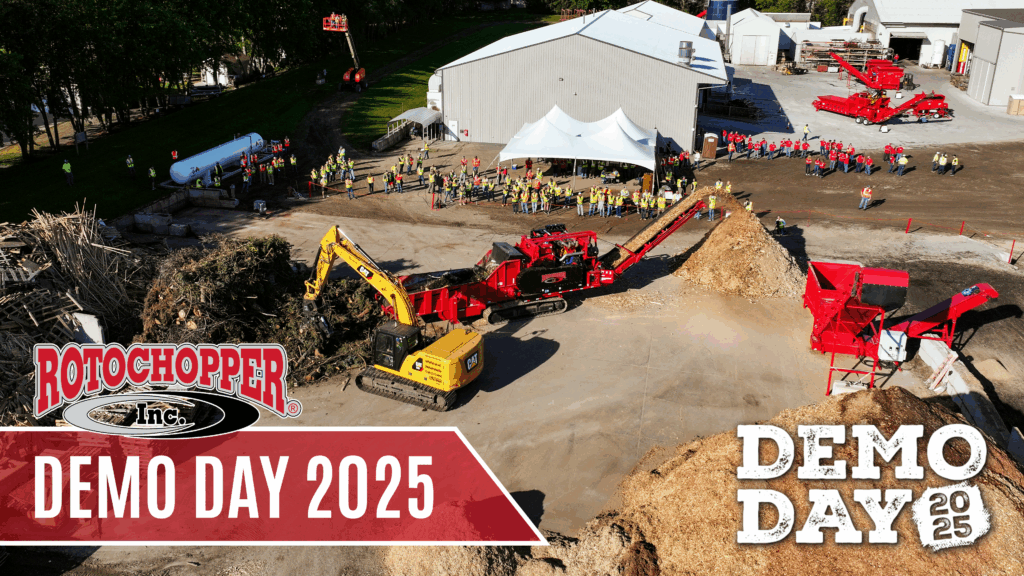

For over 35 years, Rotochopper has been creating innovative solutions for a number of different use cases, operations and industries. Our focus on your operational needs allows us to create a solution that will increase efficiency and productivity, whether that’s a grinder, shredder, screener, multi-stage system, trailer loading auger system or conveyor system, or any combination of these pieces of equipment.

View Equipment

Factory-Direct Support

Rotochopper’s factory-direct support model offers unique benefits in an industry full of dealers. We are focused exclusively on Rotochopper equipment, allowing us to provide expert guidance for you and your operation. Additionally, everyone on our service team spends time in the field, whether they are based out of the factory or their territory office, so when they arrive at your location – you can trust that their expertise and knowledge will meet your expectations.

View Customer Support

Why Choose Rotochopper Grinding Equipment?

In today’s business world, it’s often hard to know who you’re dealing with. Are you dealing with an independent company or some small subsidiary of some large company? When you work with Rotochopper, you can work with a company that’s devoted to the spirit and the actuality of independence. So, when we make decisions were not making decisions on behalf of some larger entity but rather focused on your needs and ours. If you want a simple, elegant solution to the complicated problem of recycling organics – Rotochopper is the independent operator for you.

TAKE THE NEXT STEP

Connect With Us

Our sales and service teams are available and ready to answer any questions you may have. We look forward to hearing from you.

Contact Sales Contact Service Available Equipment

Contact Us

Rotochopper, Inc.

217 West Street, PO Box 295

St. Martin, MN 56376

Phone: 320-875-9950

Email: info@rotochopper.com

Stay Connected

Connect with Rotochopper to see our machines in action, new products, news and events!

Join our Email List to stay up to date on the latest product releases and updates, industry news, and offers.

We would love to see your photos and videos! Tag #Rotochopper in your posts to share them with us.