Rotochopper electric horizontal grinders combine the simplicity and efficiency of electric motors with our hallmark versatility and “Perfect In One Pass” grinding precision.

Precision Grinding

Our electric grinders offer “Perfect In One Pass” simplicity for colored landscape mulch, animal bedding, and other products with demanding specifications.

Unmatched Efficiency

We designed a dedicated line of electric-powered grinding systems to optimize the enhanced efficiency, uptime, and clean operation of electric power.

Electric Horizontal Grinder Models

Select a machine to find the right electric grinding solution for your raw materials.

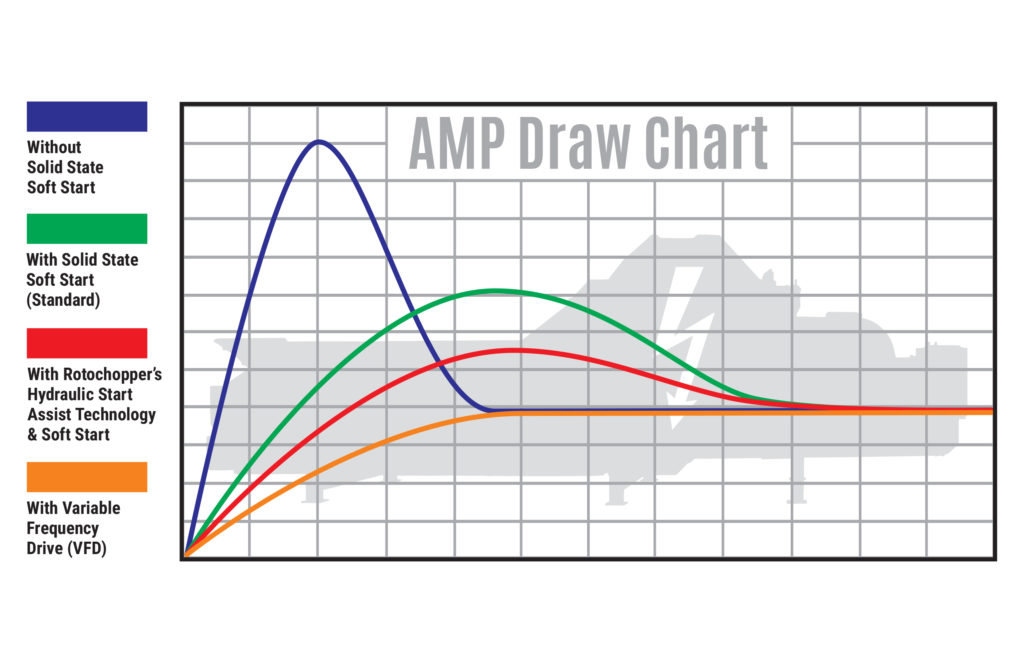

Reducing Start-Up Costs

Rotochopper offers several options to minimize the cost of operating electric grinders by reducing the amperage surge that normally occurs at start-up. A more controlled, gradual start-up means less wear on drive belts and other components. Additionally, power companies typically apply fees to amperage spikes from large electric motors. These systems will reduce or even eliminate these fees. We will work with you to determine the best option for your operation – Solid State Soft Start, Rotochopper’s patented Hydraulic Start Assist paired with Solid State Soft Start or utilizing a Variable Frequency Drive (VFD).

“Perfect In One Pass”

Rotochopper electric grinding systems were designed to give you the particle size your business requires with the ease-of-operation you need from electric grinders. Each one of our electric machines was designed to maximize efficiency and maintain consistent product, allowing you to focus on other aspects of your business.

Unmatched Uptime

Rugged reliability and operating simplicity made our electric grinder series the natural choice to match steady streams of raw material for a variety of producers including pallet recyclers, transfer stations, power plants, and other fiber processing facilities. Rotochopper produces equipment and horsepower solutions for producers of any size, whether you need a high-volume B-66E or a SB-24E inline slab processor.

Seamless Integration

Our electric machines are designed to integrate seamlessly with a Rotochopper hammermill to provide a one-pass solution for animal bedding, fuel pellets, and other short-fiber products. Wood waste enters the grinder and exits the hammermill as uniform fine-texture material.

"Our wood waste has gone from an unnecessary expense to a large part of our business. We used to pay someone to haul it off, now ground product has become 20% of our income."

— Henk Vrugteveen, Oxford Pallet and Recyclers

Contact Us

Rotochopper, Inc.

217 West Street, PO Box 295

St. Martin, MN 56376

Phone: 320-875-9950

Email: info@rotochopper.com

Stay Connected

Connect with Rotochopper to see our machines in action, new products, news and events!

Join our Email List to stay up to date on the latest product releases and updates, industry news, and offers.

We would love to see your photos and videos! Tag #Rotochopper in your posts to share them with us.