We are delighted to announce the addition of Mike Elling to the Rotochopper team as Chief Financial Officer (CFO). In […]

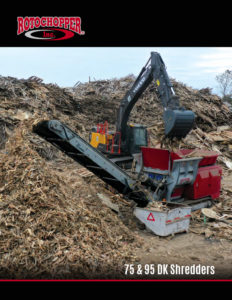

Learn More95 DK

Shredder

Powerful & Reliable

The 95 DK Shredder boasts a powerful engine, long working length, aggressive intake, and twin shaft rotor cutting system to efficiently processes even the toughest materials.

Contact a Sales Rep

Featured Specifications

The exceptionally reliable 95 DK shredder is easy to maintain, and can tackle a variety of materials including railroad ties, sorted & unsorted C&D waste, and large chunk wood.

-

Advantages

Multiple Rotor Configurations

Choose the rotor shafts that suit the material that you are shredding, whether that be railroad ties, stumps, municipal solid waste, and sorted and unsorted C&D waste.

Adjustable Discharge Conveyor

The hydraulically adjustable conveyor allows you to easily shred directly into another piece of equipment, trailer, or bunker.

Robust Engine

The powerful 770 hp diesel engine delivers efficient shredding capabilities, while being fuel-efficient, quiet and eco-friendly.

-

Exclusive Features

Dual Shaft Cutting System

The twin-shaft cutting system of the 95 DK is incredibly productive and efficient at processing even the toughest materials.

Intelligent Hopper System

Hydraulic double tilting hopper system optimizes and allows for even material feeding of your materials and consistent output.

Easy to Use Interface

Use the intuitive touch screen display or remote control to safely operate and control the shredder.

Tracked Chassis

An independently maneuverable track system allows you to move the 95 DK on-site with a remote control.

Hydrostatic Drive

Achieve high output from the self-regulating hydrostatic double drive providing up to 354,029 ft. lb. of torque.

Hydraulic Cross-Belt Magnet

The optional cross-belt magnet helps remove ferrous metal from your final product.

-

Videos

Rotochopper 95DK Mobile Shredder

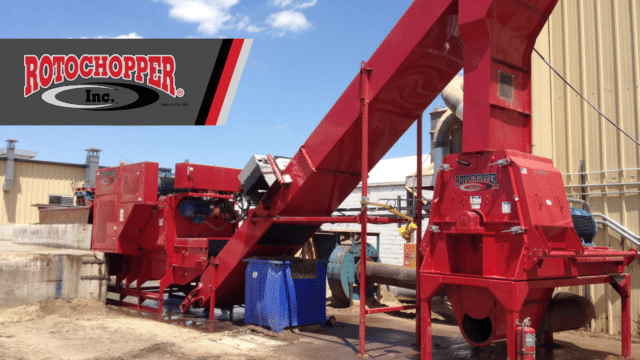

The 95DK Shredder takes mobile shredding to the extreme with maximum output and full mobility. The DK Series shredder boasts a powerful twin-rotor cutting system that is exceptionally reliable, easy to maintain and provides consistent output at a low rate of energy per ton of shredded material. In this video, the 95DK shreds pallet scraps and C&D waste before the material enters Rotochopper’s B-66L horizontal grinder, minimizing the potential for metal entering the grinder and offers efficiency by streamlining the shredding and grinding process.

Subscribe to our YouTube Channel - Industries

-

Additional Specs

Dimensions

- Length – 30’ 2” (9.2 m)

- Width – 11’ 4” (3.4 m)

- Height – 10’ 6” (3.2 m)

- Weight – 103,000 lbs. (46,720 kg)

Shredding Table

- Table opening – 3’ 5” x 7’ 8” (107 x 239 cm)

- Rotor lengths – 8’ 2” (250 cm)

- Rotor diameter – 2’ 9” (87 cm)

Options

- Choice of fine or rough rotors

- Hydraulically adjustable cross belt magnet

- Rubber pads for crawler tracks

- Dust suppression system with water source

95DK Shredding Table

Watch the power of the Rotochopper 95DK Series Shredder’s twin shafts, effortlessly maneuvering through challenging materials during processing. These twin shafts demonstrate unparalleled power and torque, ensuring seamless handling of the most demanding waste materials. The powerful hydrostatic drive allows the shafts to pulverize diverse materials.

View Cutting System Options

"The 95DK has provided us reliability, great throughput, and we know that it is going to keep up with our material."

— Mike Ledieff, C.A.R.T.S.

Additional Resources

How The Rotochopper RMT Hammermill Opens New Market Opportunities

In an era where innovation intersects with sustainability, Rotochopper is revolutionizing the way industries approach waste management and recycling. In keeping […]

Learn MoreHow to Connect a Rotochopper Horizontal Grinder to a Generation II Transport Dolly

This Rotochopper University Instruction Guide outlines the steps for connecting a grinder to a transport dolly efficiently. It begins […]

Learn More