Our versatile infeed design maintains consistent feed rates for a variety of feedstocks—whole trees, round corn stover bales, yard waste, bark, green slab wood, palm fronds, wood chips, tomato vines, food waste, and many others.

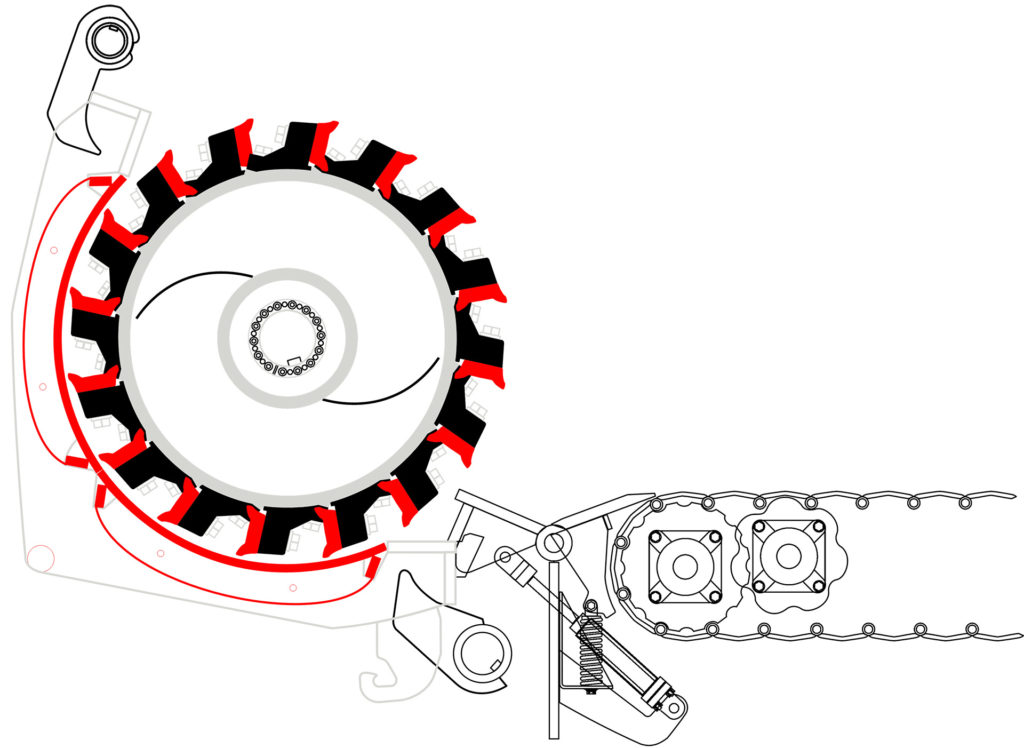

Steel Slat Conveyor Belt

A steel slat infeed conveyor provides smooth feed rates for a wide range of raw materials—forestry slash, round bales, slab wood, corn cobs, wood chips, and even wet, dense bark. With this conveyor design, flat steel slats are hinged together to form a continuous surface. Because loose materials rest on top of the belt, this conveyor design provides cleaner operation with less wear than drag chain conveyors.

Aggressive Powerfeed Roller

Each Rotochopper horizontal grinder features an aggressive powerfeed drum to ensure continuous feeding and optimal efficiency. Deep serrated plates mounted to the drum effectively control feed rates for solid feedstocks like logs and pallets, as well as lighter materials like yard waste and corn stover. The powerfeed and infeed speed can be adjusted independently.

Infeed Transition System

Our unique infeed transition system maximizes the advantages of the steel slat conveyor, allowing feed material to flow smoothly from the infeed conveyor to the grinding chamber. Just before the grinding chamber, a floating scraper plate rests on top of the conveyor belt, forcing raw material into the rotor for proper grinding. This smooth transition prevents small particles from bypassing the grinding process, ensuring better particle size control and a cleaner work site. Grinders that lack a smooth transition method lose particles that fall directly on to the collection conveyor, compromising finished product control. Best of all, our transition system accomplishes this without augers or other power-driven parts, making it the simplest, most reliable transition method available. *Standard on select models.

Slab Ramp

Our patented slab ramp system offers a simple yet remarkably effective method for controlling feed rates with pliable feedstocks that can plug other grinders instantly. Adjustable in less than 5 minutes, this simple design is the difference between downtime and steady uptime.

Equipment Featuring Infeed Systems

The best thing about the B-66 is that after a 10 hour day feeding the machine you're not exhausted.

— Jeff Hook, California Orchard Removal & Grinding Inc

Want to Learn More?

Contact A Sales RepRotochopper, Inc.

217 West Street, PO Box 295

St. Martin, MN 56376

Phone: 320-875-9950

Email: info@rotochopper.com

Stay Connected

Connect with Rotochopper to see our machines in action, new products, news and events!

Join our Email List to stay up to date on the latest product releases and updates, industry news, and offers.

We would love to see your photos and videos! Tag #Rotochopper in your posts to share them with us.