Improved animal nutrition and bedding is one of the simplest ways to increase animal health and performance. Nothing delivers the particle specifications and throughput volumes you need like Rotochopper grinding equipment.

Superior Bedding at a Lower Cost

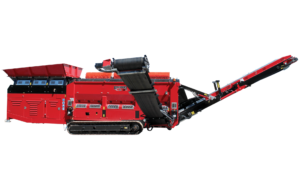

In many regions throughout the world, wood fiber animal bedding is a growing market that rivals even colored mulch in profitability and growth potential. Nothing turns wood waste into premium animal bedding more efficiently than Rotochopper grinding solutions. Rotochopper equipment offers “Perfect In One Pass” grinding simplicity for a broad range of materials, from pallets to round wood, producing high quality animal bedding at the lowest cost per unit.

Complete Grinding Solutions for Bedding & Nutrition

The particle size control that makes Rotochopper the standout choice for animal bedding also allows Rotochopper to stand out as a solution provider for high-volume animal feed grinding. If you need to grind bales, grain, or non-traditional nutrition sources, look no further than the feed grinding capabilities of Rotochopper equipment.

High-Moisture Feed Grinding

Unmatched in fine grinding efficiency for wet or dry materials, Rotochopper grinders reduce high-moisture shell corn to 100% ¼ inch (6 mm) minus in a single pass, with no un-cracked kernels. Only a Rotochopper grinder combines this level of grinding accuracy with the rugged engineering to grind bales, wood waste, and other raw materials, optimizing the digestibility and palatability of a wide range of feed sources.

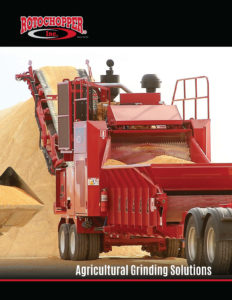

Agricultural Grinding Solutions Brochure

View, download and print the full brochure by clicking the link below.

Agricultural Grinding SolutionsAgricultural Grinding Equipment

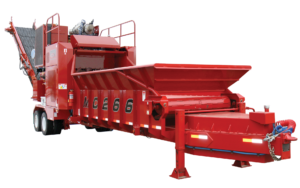

Two Stage Fine Grinding System

This video shows how a Rotochopper multi-stage fine grinding system takes raw wood waste down to animal bedding in a single pass.

Additional Videos

- Rotochopper MT175 Trommel Screen

- Rotochopper Inc. | MC-266 Horizontal Grinder

- Rotochopper Inc. | FP-66 B-Series

- Rotochopper SB-24E: Grinding Slabwood and Sawmill Waste

- Rotochopper FP-66: Grinding High-Moisture Shell Corn

- B-66T Grinding High Moisture Shell Corn

- High-Moisture Shell Corn Grinding

- Rotochopper MC-266 Grinding High-Moisture Shell Corn

- Two Stage Fine Grinding System

- B-66 Grinding Big Square Straw Bales

"Poultry markets prefer lighter, fluffier bedding materials, and the Rotochopper two-stage system can produce this type of bedding efficiently…We grind it down to the size of wheat or oats."

— Wade Kohler, Pioneer Packaging

Want to Learn More?

Contact A Sales RepRotochopper, Inc.

217 West Street, PO Box 295

St. Martin, MN 56376

Phone: 320-875-9950

Email: info@rotochopper.com

Stay Connected

Connect with Rotochopper to see our machines in action, new products, news and events!

Join our Email List to stay up to date on the latest product releases and updates, industry news, and offers.

We would love to see your photos and videos! Tag #Rotochopper in your posts to share them with us.