For more than 30 years, Rotochopper grinders have set the standard for efficiently and affordably recycling pallets into premium fiber products, like colored landscape mulch, fiber fuels, and animal bedding.

Pallet Grinding Simplified

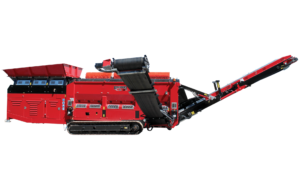

Our “Perfect In One Pass” grinding technology recycles pallet scrap into premium products with remarkable speed and operational simplicity. Rotochopper electric grinders offer unmatched efficiency and uptime for pallet grinding systems with 3-phase power. Our diesel grinders offer the same precision grinding, plus the added mobility of wheels or tracks for convenient portability.

End Product Versatility

Rotochopper grinders are fully equipped to help pallet grinding operations transform waste into high-quality landscaping mulch, animal bedding, or biofuel with efficiency and superior particle size consistency. Our grinders can be paired with our trommel screen, colorizer system, and the Go-Bagger® 250, allowing you to grind, color, and bag your end product, streamlining the process and increasing your operation’s efficiency. With the mulch industry experiencing a high level of growth, it’s an opportunity Rotochopper is prepared to help you take advantage of.

Fine Grinding Solutions

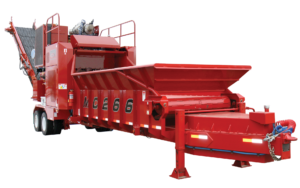

Rotochopper multi-stage pallet recycling systems can convert pallet waste to animal bedding or short fiber fuels in one smooth pass. A Rotochopper multi-stage grinding system combines a grinder with an in-line hammermill. The grinder reduces whole pallets and crates to coarse fiber. Magnetic metal removal systems separate nails and other steel as the coarse fiber flows to the hammermill, where it effortlessly refines the fiber to final specifications.

Complete Pallet Recycling Systems

Rotochopper is proud to offer much of the equipment needed to provide your operation with a complete pallet recycling system. Whether you’re trying to automate your existing operation or build from the ground up, Rotochopper carries conveyor systems, hammermills, and trailer-loading auger systems. Reduce unnecessary material handling and process pallet waste without compromising productivity. With 30 years of industry expertise, we understand your pallet grinding system is unique to your operation, and we offer a consultative approach to provide you with recommendations for efficient solutions.

Pallet Grinding Solutions Sell Sheet

View, download and print the full sell sheet by clicking the link below.

Pallet Grinding SolutionsPallet Recycling Equipment

Multi-Stage Fine Grinding Solutions Featuring LVM Materials

Rotochopper’s Multi-Stage Fine Grinding System provides an integrated, end-to-end solution to efficiently produce short length fiber products such as animal bedding, wood pellets, and suspension burner fuel. Our multi-stage systems combine the proven versatility of our horizontal grinders with the fine grinding efficiency of a hammermill to create a seamless process for your operation.

In this video, at a recycling facility, Rotochopper’s Multi-Stage System includes an electric EC-366 horizontal grinder, hopper, conveyor, and RMT Hammermill. With the installation of the solution this operation has seen the benefits of a smaller equipment footprint, an increase in production, a lower cost of operation and a better finished end product, which has all led to an improved bottom line.

Additional Videos

- Electric 75E Shredder

- B-66L Grinding Pallet Slabs

- MC-266 Grinding Slab Wood & Sawmill Waste

- MC-266 Grinding Pallet Waste

- Rotochopper DK Series Shredders

- Rotochopper MT175 Trommel Screen

- B-66 L-Series Horizontal Grinder

- MP-2 Horizontal Grinder

- Rotochopper Inc. | MC-266 Horizontal Grinder

- Rotochopper EC-366: Grinding Sawmill Waste & Slabwood

- Rotochopper: Colored Mulch Solutions

- Rotochopper FP-66 Grinding Wood Waste

- Rotochopper FP-66 Grinding Pallets

- Rotochopper EC-366 grinding pallets

- Rotochopper B-66 E Grinding Pallets

"Adding a Rotochopper EC-256 to my pallet operation was one of the best business decisions I've made."

— Henk Vrugteveen, Oxford Pallet & Recyclers, Ltd.

Want to learn more about turning pallet waste into profitable opportunities?

Contact A Sales RepRotochopper, Inc.

217 West Street, PO Box 295

St. Martin, MN 56376

Phone: 320-875-9950

Email: info@rotochopper.com

Stay Connected

Connect with Rotochopper to see our machines in action, new products, news and events!

Join our Email List to stay up to date on the latest product releases and updates, industry news, and offers.

We would love to see your photos and videos! Tag #Rotochopper in your posts to share them with us.