Rotochopper grinders have a range of mechanisms to protect your machine from detrimental downtime including our StopWatch monitoring system and ferrous metal removal devices.

StopWatch Monitoring System

How It Reduces Damage

The StopWatch system monitors rotor vibration to reduce damage from severe impacts with un-grindable objects, rotor imbalance, and other causes of damaging vibration. If an un-grindable object enters the grinding chamber, the StopWatch will sense the spike in vibration and instantly stop and reverse the infeed conveyor. By reversing the infeed conveyor, the StopWatch system lowers the chance of the rotor repeated striking the tramp object. Once the StopWatch is triggered, the infeed will remain stopped, allowing the operator to ensure the grinder is in proper condition before resuming operation.

Matched to Your Grinding Applications

To use the StopWatch, the operator sets an acceptable vibration level through the electronic controller. Since different feedstocks produce different vibration levels, the operator can quickly fine tune the vibration threshold to match the grinding application. Adjusting the vibration threshold can help avoid unnecessary stopping of the infeed from normal operating vibration.

*StopWatch Monitoring System is available for select models.

Ferrous Metal Removal

Rotochopper grinders and hammermills can be equipped with a variety of metal removal methods to help ensure you get end products that are free of ferrous metals.

Magnetic Head Pulley

Magnetic head pulleys are effective for removal of light ferrous metal, like pallet nails. The separated metal travels down the underside of the conveyor for collection in a dumpster.

Cross-belt Magnetic Conveyor

A cross-belt conveyor is a self-cleaning plate magnet positioned above the discharge conveyor. Cross-belt conveyors offer greater levels of metal separation than magnetic head pulleys.

S-Chute Magnet

An S-chute magnet provides redundant metal removal for a hammermill to help ensure the material flowing into the hammermill is free of ferrous metal.

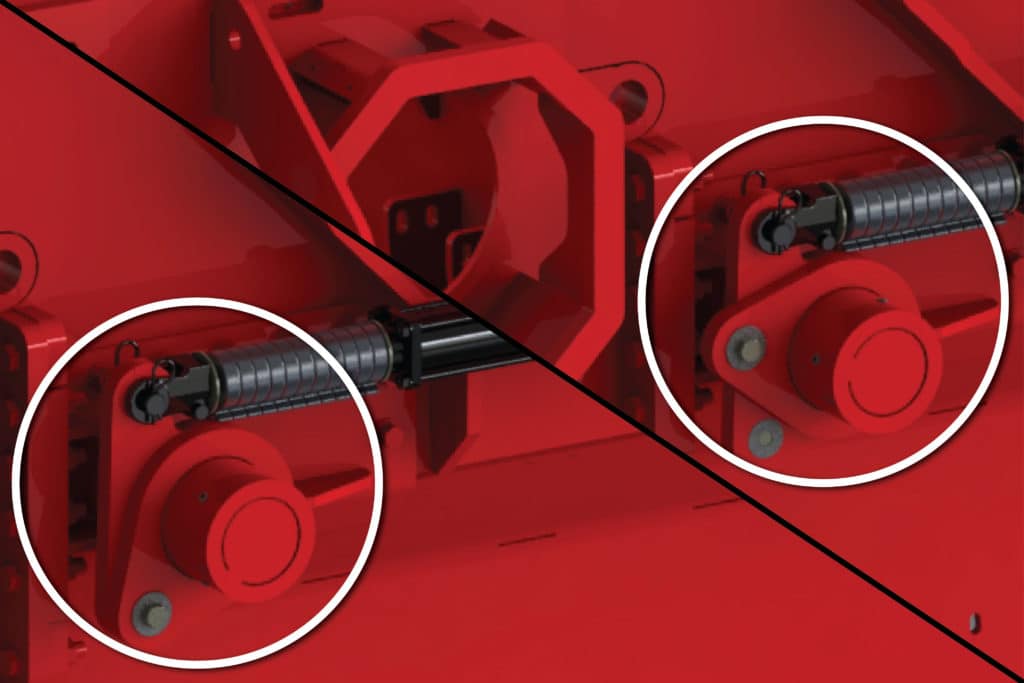

Shear Bolt Damage Protection

Upon severe impact with an un-grindable object, shear bolts in the screen cam arms may shear, which allows the screen, cradle, and slab ramp to drop away from rotor, in order to limit damage.

Damage Prevention Available for

Contact Us

Rotochopper, Inc.

217 West Street, PO Box 295

St. Martin, MN 56376

Phone: 320-875-9950

Email: info@rotochopper.com

Stay Connected

Connect with Rotochopper to see our machines in action, new products, news and events!

Join our Email List to stay up to date on the latest product releases and updates, industry news, and offers.

We would love to see your photos and videos! Tag #Rotochopper in your posts to share them with us.