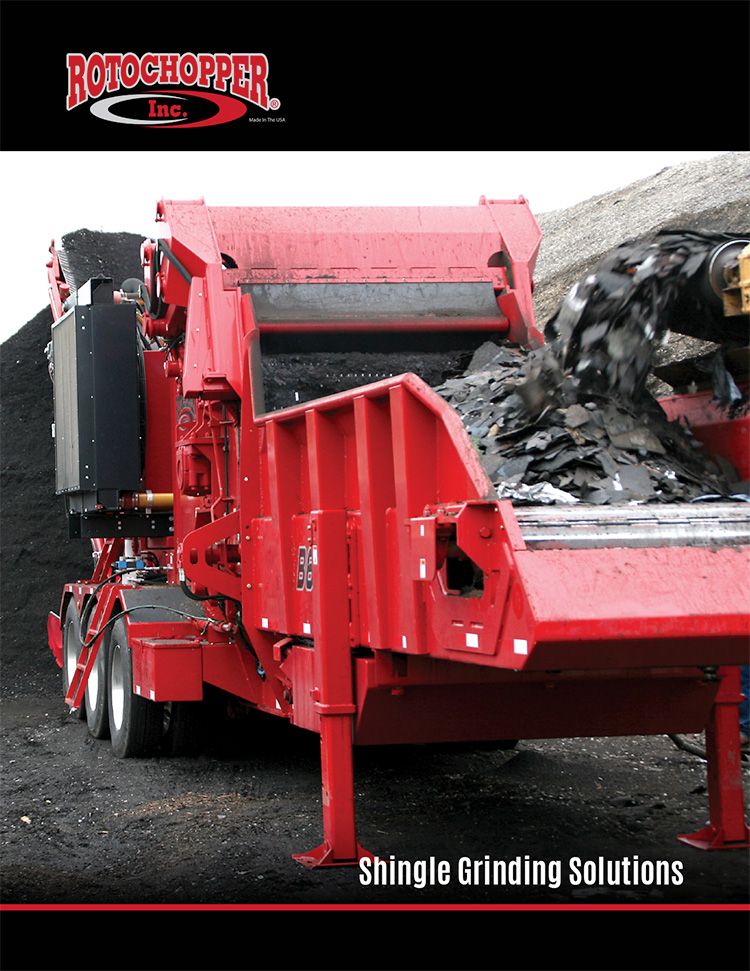

The abrasiveness, pliability, and cohesiveness of asphalt shingles make it one of the most challenging materials to recycle efficiently. Rotochopper asphalt shingle grinders offer the versatility, controlled wear, and consistent uptime necessary for these highly abrasive feedstocks.

Asphalt Shingle Recycling

Rotochopper shingle grinders are packed with exclusive features that add up to one simple difference—a lower cost per ton of finely ground shingles. Before we engineered our first shingle grinder, we worked directly with customers to develop the features that make Rotochopper shingle grinders more user-friendly and cost-effective for recycling reject and tear-off shingles than any other grinding or shredding equipment.

Lower Wear Costs

When grinding an abrasive feedstock, wear costs and potential downtime challenges are sure to be top of mind. Starting off with the right equipment and specialized wear parts for the job will certainly mitigate these challenges. A Rotochopper grinder equipped with our high abrasion package, water spray system and the appropriate wear parts will offer lower wear costs and more uptime than the wood grinders typically used to recycle shingle waste.

End Product Precision

State and provincial DOTs typically specify a maximum particle size of 1/2″ (12 mm) or 3/8” (11 mm) minus for RAS used in public road surfaces. To get to this specification, fine grinding of this abrasive feedstock is necessary. Rotochopper horizontal grinders are known for their end product precision and control. Our team will ensure your horsepower, rotor, teeth, and screen specifications are aligned to meet the end product specifications you need.

Multi-Purpose Shingle Grinders

For companies that need the versatility to grind more than just asphalt shingles, our multi-purpose shingle grinders bring advantages to companies grinding asphalt shingles in addition to yard waste, wood waste, and other feedstocks. These advantages include – consistent parts availability, easy access to wear parts, and our patented screen change system. Operators can quickly switch screens at the ground level to meet various end product specifications while minimizing downtime.

Rotochopper Advantage

The individual advantages designed into Rotochopper shingle grinders add up to one big difference where it matters most: your bottom line. Once you see the Rotochopper advantage in action, you will understand why Rotochopper is the most trusted name in asphalt shingle recycling.

Shingle Grinding Solutions Sell Sheet

View, download and print the full sell sheet by clicking the link below.

Shingle Grinding SolutionsShingle Recycling Grinding Equipment

"With less wear and maintenance time, we can focus on our business, not our grinder."

— John Krueger, Greensite Recycling

Additional Resources

How to Disconnect a Rotochopper Horizontal Grinder from a Generation II Transport Dolly

To safely disconnect a transport dolly from a Rotochopper Generation II transport dolly, start by parking on level ground and […]

Learn MoreHow to Connect & Disconnect a Rotochopper Generation II Transport Dolly from a Tow Vehicle

This Rotochopper University Instruction Guide outlines the steps for connecting and disconnecting a transport dolly from a tow vehicle. […]

Learn MoreRotochopper Welcomes Mike Elling as Chief Financial Officer

We are delighted to announce the addition of Mike Elling to the Rotochopper team as Chief Financial Officer (CFO). In […]

Learn MoreWant to Learn More?

Contact A Sales RepRotochopper, Inc.

217 West Street, PO Box 295

St. Martin, MN 56376

Phone: 320-875-9950

Email: info@rotochopper.com

Stay Connected

Connect with Rotochopper to see our machines in action, new products, news and events!

Join our Email List to stay up to date on the latest product releases and updates, industry news, and offers.

We would love to see your photos and videos! Tag #Rotochopper in your posts to share them with us.