In many industries, versatility is key to success, and in the waste reduction business, that versatility starts with the ability to process tough, contaminated materials. Construction and demolition waste is one of the most challenging feedstocks to manage, but it also presents some of the greatest opportunities for recycling and reuse.

Every construction or demolition project produces waste that must be properly dealt with—either safely disposed of or recycled into new, usable products. With the right waste reduction equipment, your operation can turn both sorted and unsorted C&D materials into valuable end products while keeping debris out of landfills. Shredders and grinders play a critical role in this process, breaking down bulky materials and preparing them for efficient construction waste processing.

The Challenges of Construction and Demolition (C&D) Waste

Construction and demolition projects generate large volumes of potentially contaminated debris that must be managed carefully. C&D waste is made up of building materials such as wood, concrete, drywall, and asphalt shingles—many of which are highly abrasive and often riddled with metal, nails, and other non-grindable contaminants. To reduce damage to machinery and avoid expensive repairs, this material should be pre-processed properly through a shredder before going through the grinder.

C&D debris is processed in several ways depending on material type and handling strategy. Waste can be converted to a second product, but not all material can. Unrecyclable waste must be hauled to a landfill—which charges tipping fees by volume of the load—to be properly disposed of. As C&D waste is bulky, these fees can get high. By grinding or shredding waste, load volume is reduced, which cuts costs over time.

Sorted vs. Unsorted C&D Waste

How C&D is handled onsite has a major impact on its end use:

- Sorted waste can be processed into higher-value products such as boiler fuel, animal bedding, mulch, or reclaimed asphalt shingles (RAS)

- Unsorted waste can still be effectively recycled into aggregates, or alternative fuel, even when materials are mixed and contaminated

No matter the approach, successful demolition waste recycling depends on durable equipment designed to withstand abrasion, contamination, and high-volume processing.

Shredders vs. Grinders in C&D Waste Processing

Highly contaminated C&D streams often require multiple stages of size reduction. Shredders are commonly used to pre-process C&D, removing metal and reducing material size before it reaches a grinder. Grinders then produce consistent, spec-ready end products.

Read more on our blog to learn when each machine is best suited.

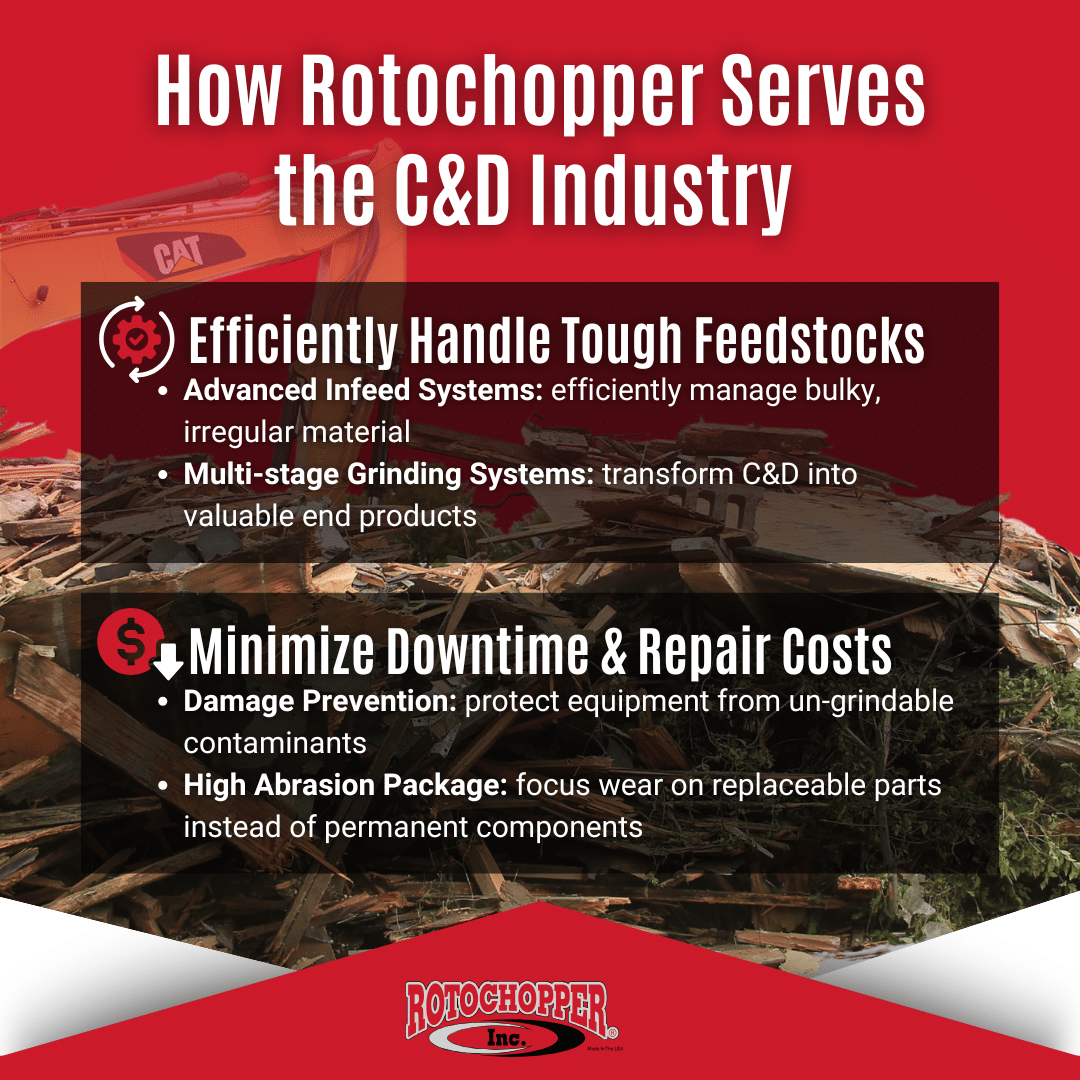

How Rotochopper Helps Recycle C&D Waste

Rotochopper equipment is engineered to handle the toughest feedstocks with ease. Our shredders and grinders allow operators to convert waste into valuable products like ground asphalt, mulch, wood pellets, and wood chips while minimizing downtime and repair costs.

Rotochopper’s waste processing equipment is built with contaminated feedstocks in mind, offering features that protect critical components and improve efficiency:

- Advanced feed systems on select models efficiently manage bulky, irregular material

- Purpose-built designs help keep C&D waste out of landfills, supporting sustainability goals

- Our preventative maintenance program helps reduce unexpected downtime and extend equipment life

Multi-stage grinding systems can also transform C&D wood waste into products like animal bedding—eliminating extra handling and improving overall efficiency.

Integrated Grinding Systems Built for Abrasion

Rotochopper grinders integrate seamlessly into complete grinding systems and pair well with Rotochopper shredders and screeners to safely and efficiently recycle construction and demolition waste. These systems are designed to process abrasive materials without sacrificing performance or longevity.

Damage Prevention and Durability (Select Models)

To protect equipment from un-grindable contaminants, Rotochopper offers advanced safeguards, including:

- StopWatch monitoring systems that stop and reverse the infeed when contaminants are detected

- Magnetic separation features to remove ferrous metal

- Shear bolt damage prevention to protect teeth, rotors, and screens

For operations processing extreme materials, Rotochopper’s high abrasion package is designed to focus wear on replaceable parts instead of permanent components, extending machine life and reducing maintenance costs.

Build a Smarter C&D Recycling Operation with Rotochopper

When it comes to C&D waste recycling, having reliable, versatile equipment makes all the difference. Rotochopper delivers durable, effective solutions backed by factory-direct support and industry expertise. Whether you’re processing sorted or unsorted materials, Rotochopper helps you reduce waste volume and hauling fees, recover value, and keep construction and demolition debris out of landfills.

Ready to improve your operation’s efficiency and versatility? Contact a Rotochopper sales representative to learn how our shredders, grinders, and complete grinding systems can support your construction waste processing goals.