Many industrial operations produce end products through their grinding process that can supplement their revenue and maximize profits. One of the most popular and versatile end products is mulch, which is typically made from wood waste like ground pallets and woodchips, but is sometimes composed of leaves, straw, and even rubber. While it has many applications, it is primarily used by landscapers, gardeners, and homeowners to protect plants and nourish the soil around a home or business.

Because mulch can be made with many materials, operations across industries can use horizontal grinding equipment to produce it, from C&D disposal and green waste, to pallet recycling, and more.

Opportunities in the Mulch Market

In the last several decades, colored mulch has become popular among landscapers and homeowners because it is an affordable, easy, and eco-friendly way to improve the look of an outdoor space. In response to this increased demand, many industrial operations use mulch coloring equipment to uniformly dye or tint their mulch end products and make them more attractive to consumers.

Rotochopper’s Mulch Coloring Equipment

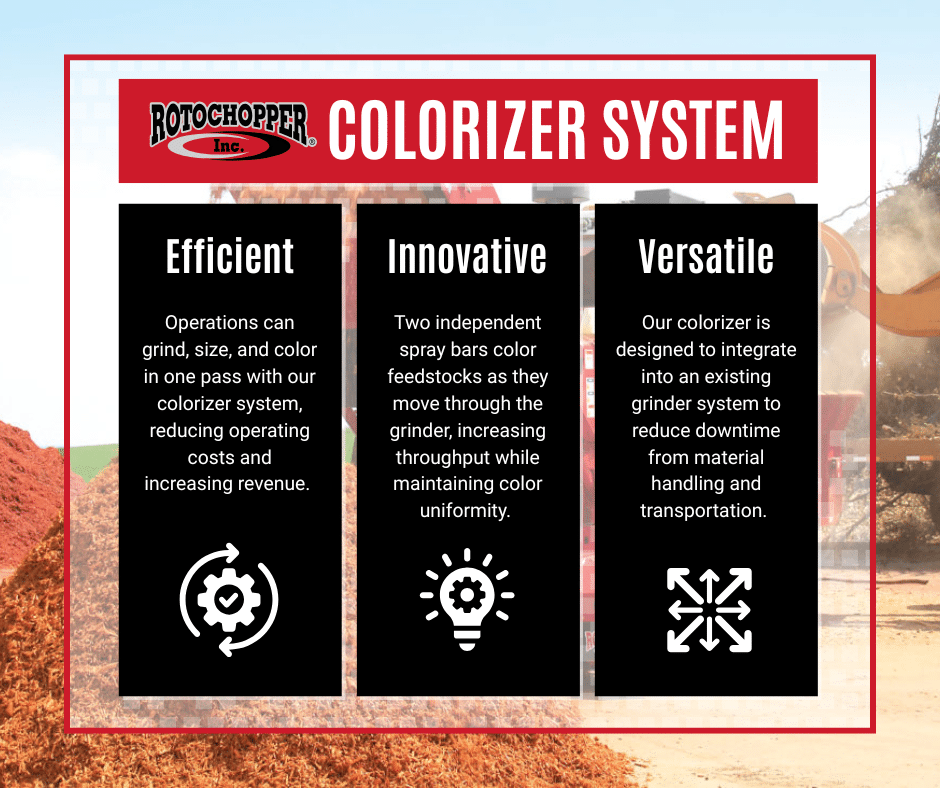

Rotochopper is proud to offer one of the most reliable, efficient, and cost-effective mulch coloring systems in the industry. Developed in 1997, our mulch coloring equipment is an optional add-on that can be fitted to almost every Rotochopper diesel grinder and uniformly coats end products with colorant. Unlike other mulch coloring equipment, Rotochopper’s system colorizes end products as they are being processed by the mulch grinder, reducing downtime, boosting operational efficiency, and eliminating the need for external mulch coloring equipment.

Efficiency

As part of an integrated grind-and-color system, Rotochopper’s mulch coloring system dyes end products as they are being processed by the mulch grinder, allowing operations to produce high-quality colored mulch in one pass. Because the entire mulch grinding and coloring process is carried out by one machine, operations can size and color end products while minimizing materials handling and slashing the time required to produce market-ready end products. Over time, operations can significantly reduce operating costs while maintaining or even increasing revenue generation.

Rotochopper’s coloring system is also engineered to leverage the strengths of our mulch grinders’ core design to efficiently and uniformly color materials. Because Rotochopper mulch grinders reliably size materials according to operations’ desired specifications, our mulch coloring system minimizes the amount of colorant needed to produce end products, further decreasing costs.

Innovation

Since it was introduced in 1997, the Rotochopper mulch coloring equipment has been built upon and improved based on our customers’ feedback and needs. Today, our generation 2 colorizer uses two independent spray bars to color feedstocks as they move through the grinder at high speed, increasing throughput while maintaining uniformity of color and operational productivity.

Versatility

Unlike other mulch coloring equipment, Rotochopper’s system is designed to integrate seamlessly into an existing grinding system. By pairing a horizontal grinder equipped with a colorizer with additional equipment, like conveyors and baggers, operations can grind, color, transport, and bag colored mulch with increased efficiency, dramatically reducing the downtime associated with materials handling and transport.

Partner With Rotochopper for High-Quality Colorizer Equipment

The Rotochopper mulch coloring system is available as an optional add-on for most Rotochopper diesel grinders. When you partner with us for mulch coloring solutions, one of our sales representatives will work with you to assess your current operation and recommend the Rotochopper coloring equipment that’s right for you.

To see how Rotochopper has helped other clients thrive in the mulch market, check out this case study from a customer in the landscape supply industry.

Contact us today to learn more about how our horizontal grinders and mulch coloring equipment can help your operation.