Regardless of industry, downsizing waste, whether from packaging or process by-product, is a great way to impact your operation’s bottom line. By reducing material size, industrial shredders make waste easier to store, transport, and dispose of. However, many shredders come with a large footprint and high price point, using space and money operations—especially small businesses—don’t have to spare.

Common Challenges Faced by Operations With (Wood) Waste Material

For operations with large volumes of waste, wood or otherwise, there are a few challenges that can impact their bottom lines. Some operations lack a reliable waste disposal solution. If they do have one, the sheer amount of waste often leaves them forced to pay high disposal costs, which are typically charged by volume.

Space is another critical consideration. Many operations cannot accommodate piles of waste or multiple dumpsters. Others do not have the space for large waste processing equipment, or the amount of waste they produce would not justify the price of the equipment needed to reduce it.

Lastly, inefficiencies in waste handling can cut into an operation’s bottom line. Moving the waste multiple times or allowing it to pile up can disrupt your workflow, leading to lost productivity and profits.

Sarlac Shredder: The Solution to Waste Reduction Challenges

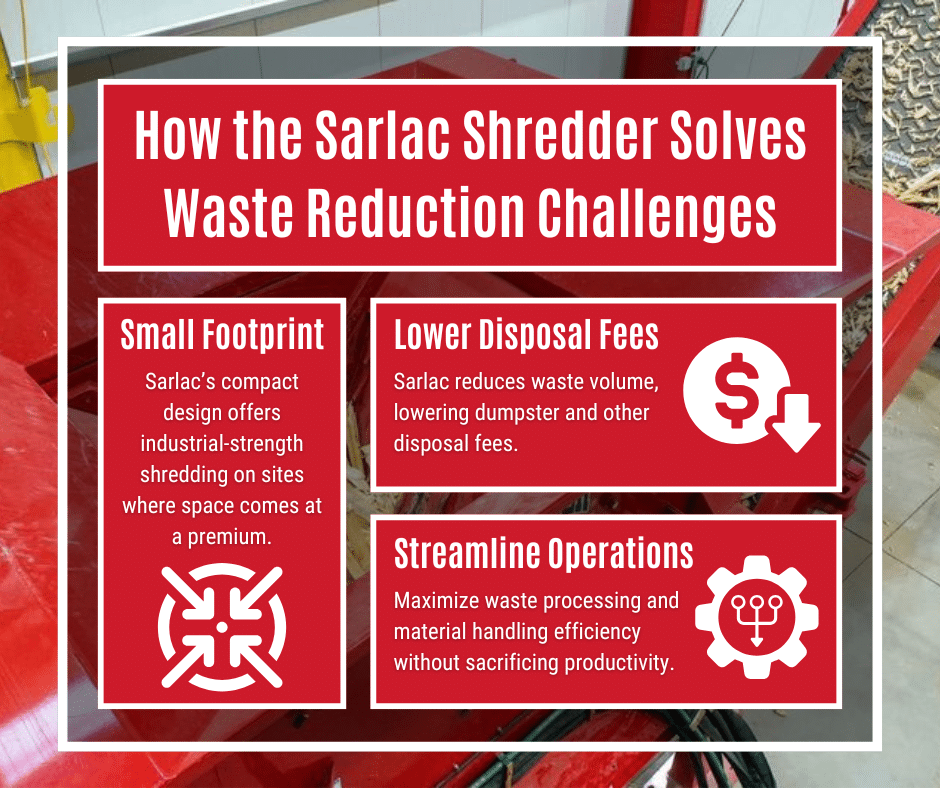

Earlier this year, Rotochopper introduced the Sarlac Shredder: an electric, shear point, low-noise shredder that excels in downsizing material. With a compact footprint and lower price point, operations regardless of size can revolutionize their waste reduction and enjoy considerable cost savings with Sarlac.

Innovatively designed with industry input, the Sarlac electric shredder boasts several features that make it ideal for operations looking to save both space and money without compromising productivity.

Compact and Space-Efficient

Sarlac electric shredder features a compact design ideal for smaller pallet manufacturers and similar businesses that lack the room or need for larger wood pallet recycling shredders. With a small footprint, Sarlac offers industrial-strength shredding on worksites where space comes at a premium.

Sarlac Shredder’s size makes it a great solution for both indoor and outdoor operations. Low-noise and reduced airborne dust production from Sarlac further enhance your workplace’s safety and the comfort of your employees.

Wide Feed Opening

The large feed opening of the Sarlac Shredder allows operations to process a significant amount of material with efficiency, increasing overall productivity. The wide feed opening also provides versatility in material feeding options and can even be automated through an in-line conveyor system.

Customizable to Operational Demands

In addition to its standard features, Sarlac Shredder can be further customized to meet the unique needs of your operation. We offer Sarlac with electric motor size options ranging from 50 to 125hp and the optional Soft Start system to manage electrical demands.

Sarlac also features a variety of conveyor configuration options and an adjustable discharge conveyor height to streamline your workflow—for example, shredding directly into a dumpster for easy disposal.

Cost-Saving Advantages of Sarlac Shredder

Reducing material volume with Sarlac Shredder offers multiple opportunities for cost savings, especially for businesses that do not have room for excess waste.

Lower Disposal Fees

With a 75% material size reduction, Sarlac reduces waste volume. This makes for easier and more cost-effective disposal, lowering dumpster and other waste processing fees.

Maximize Operational Efficiency

With a Sarlac electric shredder on their side, operations can streamline waste processing and material handling—without sacrificing efficiency and productivity. Sarlac’s compact design, affordable price point, and energy-efficient electric motor helps worksites optimize material downsizing, while its large feed opening and multiple discharge options allow it to process a variety of feedstocks.

As with all our equipment, Sarlac was designed with Rotochopper customers first in mind. It utilizes minimal wear parts for a low-maintenance shredding solution, limiting potential downtime from breakdowns. The electric motor provides consistent performance at a lower operating cost—and without the fuel costs associated with a diesel engine.

Rethink Waste Reduction with the Sarlac Shredder

Revolutionize waste downsizing and material handling with help from Sarlac—all while saving your operation valuable space and money. To learn more about whether Sarlac electric shredder is right for your operation, get in touch with one of Rotochopper’s sales representatives, or check out Sarlac in action here.