In the dynamic world of waste processing and recycling, economic opportunity and environmental sustainability often go hand in hand. Using horizontal grinders and supporting equipment, waste materials can be kept from landfills and reinvented into profitable end products, from colored landscape mulch to animal bedding and biomass fuels.

When it comes to transforming waste materials, one of the greatest opportunities lies in recycled asphalt shingles; however, this is also one of the most challenging materials to work with. With the right machines and the right shingle grinding equipment partner, recycling shingles can be a profitable pursuit that also supports green initiatives to keep building materials out of landfills.

Recycling Shingles 101

Recycled asphalt shingles (RAS) is a growing industry that is breathing new life into discarded asphalt shingles. Each year, an estimated 11 million tons of asphalt shingles end up in U.S. landfills, accounting for nearly 8% of the total building-related waste stream. These waste products are given a second life as road pavement, fuel for cement kilns, and new roofing products, offering valuable environmental benefits.

While any opportunity to reduce waste and save money is advantageous, the recycling process for this material isn’t easy. Asphalt shingles taken from roof tear-offs are coarse, pliable, and cohesive, making them challenging to recycle efficiently. Because shingles are highly abrasive, processing them can lead to increased wear on the shingle grinder and, in turn, more maintenance and potential for breakdowns.

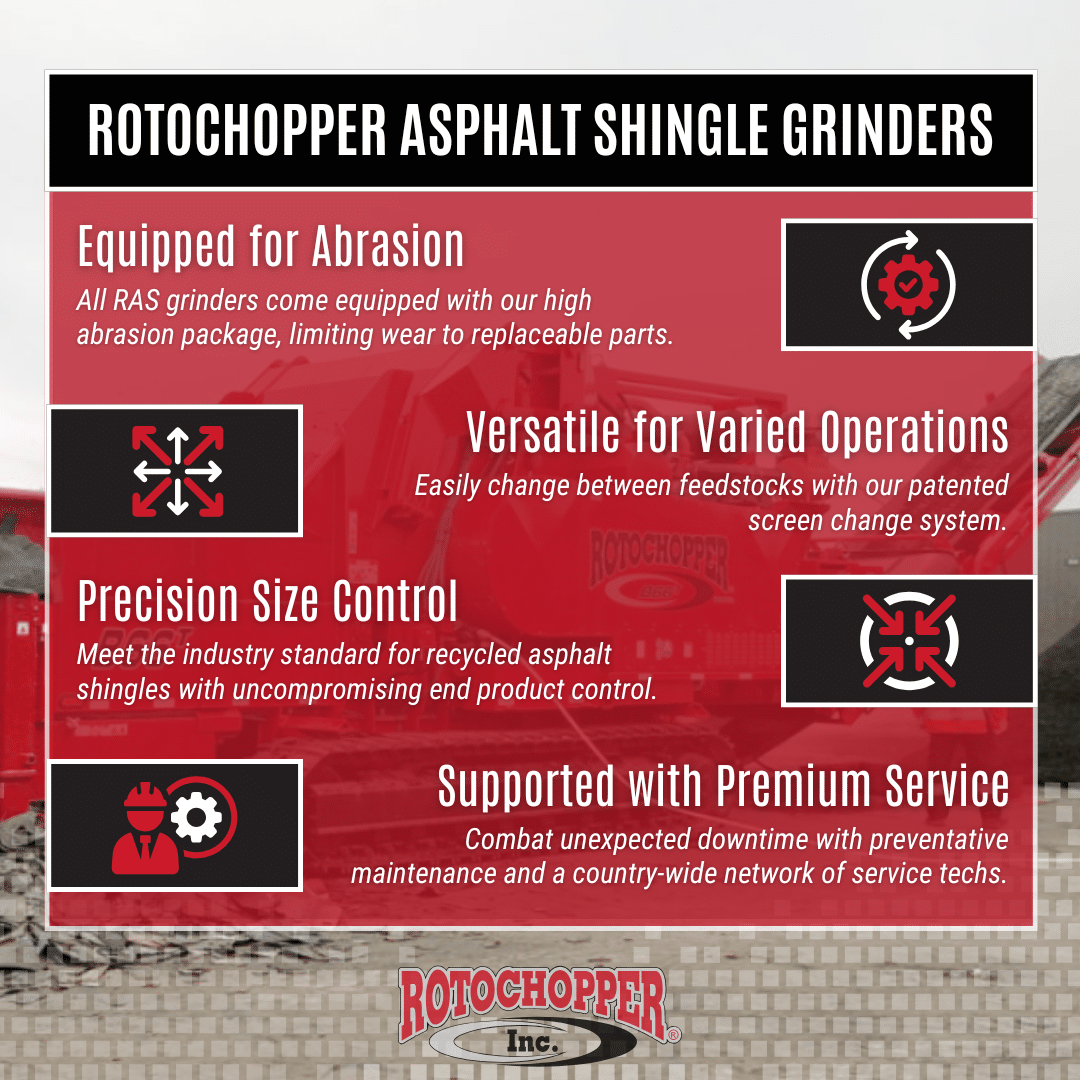

Specialized shingle grinder equipment is built to handle these abrasive feedstocks. Rotochopper shingle grinders are intentionally designed with the power and versatility necessary to recycle shingles, all while limiting excessive maintenance or downtime.

Selecting Shingle Grinding Equipment

Before we introduced our first Rotochopper shingle grinder, we worked directly with operators in the RAS market to understand exactly what they valued in a machine. From there, we developed the unique, user-friendly features that make Rotochopper shingle grinders more cost-effective for recycling reject and tear-off shingles than any other shingle grinding equipment.

When choosing your own asphalt shingle grinder equipment, consider the following selection criteria.

Buy New or Used

Although a used asphalt shingle grinder may require less upfront investment, it could end up costing more over time due to maintenance issues if not purchased from a trusted partner. Rotochopper’s refurbished equipment program ensures the grinders meet the same exacting standards we have for brand-new machines. Our refurbishment process involves a comprehensive inspection, upgrading or replacing worn components, installing custom features to meet the new operation’s needs, and thorough testing.

Focus on Features

Rotochopper shingle grinding equipment is equipped with exclusive features that add up to one simple difference—a lower cost per ton of finely ground shingles. Our water spray systems keep temperatures down and prevent plugging due to heat when recycling shingles. Our patented screen change system makes it easy to install and switch screens at ground level, with no need for overhead lifting equipment, fasteners, or special tools.

Prepare for High Abrasion

All our asphalt shingle grinders come equipped the Rotochopper high-abrasion package, which enhances natural wear resilience. Our grinding chamber keeps wear focused on replaceable parts, not permanent surfaces, while the infeed minimizes spillage and abrasion, resulting in less maintenance and more uptime.

Reflect on the Future

As you think ahead to the future of your operation, keep in mind that asphalt shingle grinders are versatile and scalable, serving operations that span various industries. With our screen change system, diversified operations, like those in the C&D industry, can easily swap between grinding different feedstocks with minimal downtime and without switching machines.

Consider Particle Size Control

State and provincial departments of transportation (DoTs) typically require a maximum particle size of less than ½ inch (12 mm) or 3/8 inch (11 mm) for recycled asphalt shingles used in public road surfaces. To achieve this specification, fine grinding of this feedstock is needed, and Rotochopper horizontal grinders are known for their end product precision and control.

Don’t Skimp on Service

When it comes to recycling shingles, quick service time can help combat unexpected downtime and safeguard your productivity and profits. If you have a new specification to meet, require replacement parts, or need to address wear, make sure you have access to expert service and support from a company you trust.

Recycled Asphalt Shingles: Getting Started

At Rotochopper, we are uniquely invested in the success and satisfaction of every business we serve. We work directly with operations to develop innovative solutions that create economic opportunities and environmental sustainability.

To learn more about how we serve the recycled asphalt shingles market, check out our RAS case study, or contact your regional sales representative today for the personalized service you need to ensure the long-term success of your grinding operation.