Part II of our series on battery recycling. Check out Part I.

In part one of this article, we looked at the high recycling rate for lead car batteries. But there’s much more to the story than the success rate of collecting batteries for recycling, as I will discuss below.

Lessons for Other Industries

Although the reasons for this high recycling rate are simple, as discussed in part I, the lessons to be gleaned from this example are actually pretty surprising. The black spot on battery recycling is a matter of how batteries are recycled.

Lesson # 1: Recycling Doesn’t Always Mean “Environmentally Friendly”

The recycling rate is impressive. But lead battery recycling is recognized as one of the worst causes of pollution across the world by the Blacksmith Institute and other environmental watch groups. Lead battery recycling facilities often have shockingly poor health and safety standards to protect workers, who are often exposed to deadly levels of lead and other chemicals.

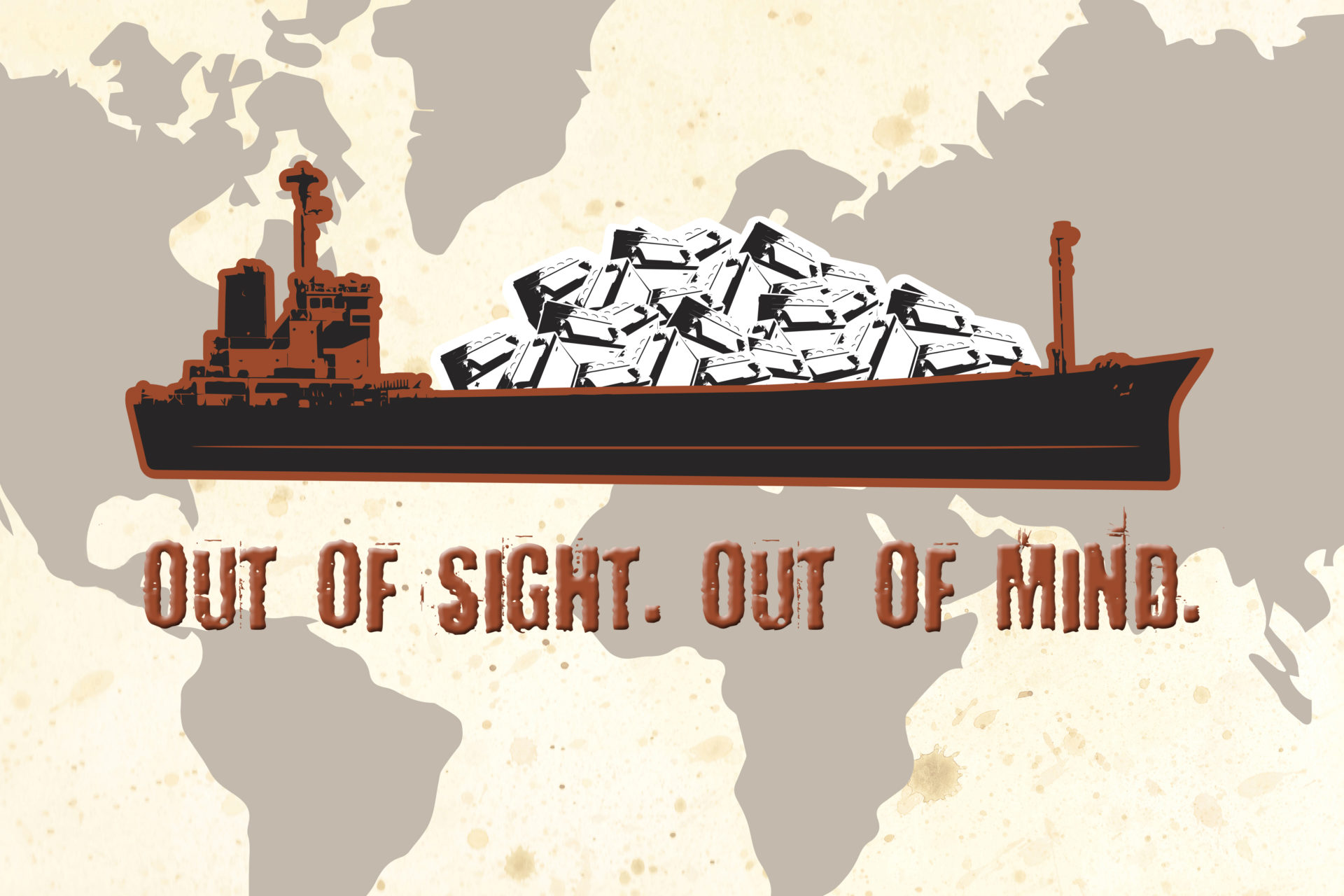

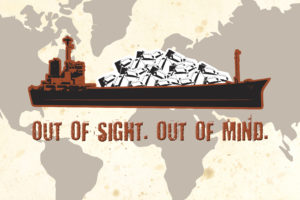

The financial incentives and government policies work to ensure a high rate of recycling but fail miserably to ensure environmental stewardship and worker health and safety. While the collection of used batteries is a streamlined, closed loop process, the actual recycling of batteries is often quite the opposite. Batteries are frequently shipped overseas and end up in facilities with deplorable conditions.

The same type of scenario applies to many other materials. A prime example is the growing E-Scrap market. The value of the materials found in electronic devices and increasing government mandates will ensure that the recycling rate will increase, but how E-scrap is recycled will remain a huge concern for the years ahead.

Lesson # 2: Transportation Determines the Long-Term Sustainability of Recycling

The battery recycling rate is so high because the transportation gap between the new product and old product is eliminated. Similarly, pallet recycling has been a huge success story for over twenty years, due in part to the short distance between new pallets and junk pallets. The same companies that build and repair pallets can recycle pallet scrap into boiler fuel, animal bedding, or landscape mulch. The availability of raw material (pallet scrap) correlates geographically to the demand for recycled products (landscape mulch and other products), so transportation between producers and consumers is minimal. The low transportation burden makes pallet recycling sustainable in the long term. The same concept applies to a variety of wood waste grinding applications.

Lesson # 3: Labor Can Trump All Other Costs

The cost of labor is a major reason why used batteries are shipped out of industrialized nations to developing nation to be recycled. By comparison, for wood waste recyclers, labor is generally a small percentage of total costs. Wood waste recycling is largely a mechanical, instead of labor intensive, process. Batteries, on the other hand, can’t be simply loaded into a machine and come out as a useable product. Used batteries may have a journey thousands of miles long to go from waste to a usable product. For wood waste, that journey can be as short as the length of a horizontal grinder.

The Future of Recycling?

What does the dark side of battery recycling teach us about the future of recycling for other materials? We will take a look in part III of this series on battery recycling.