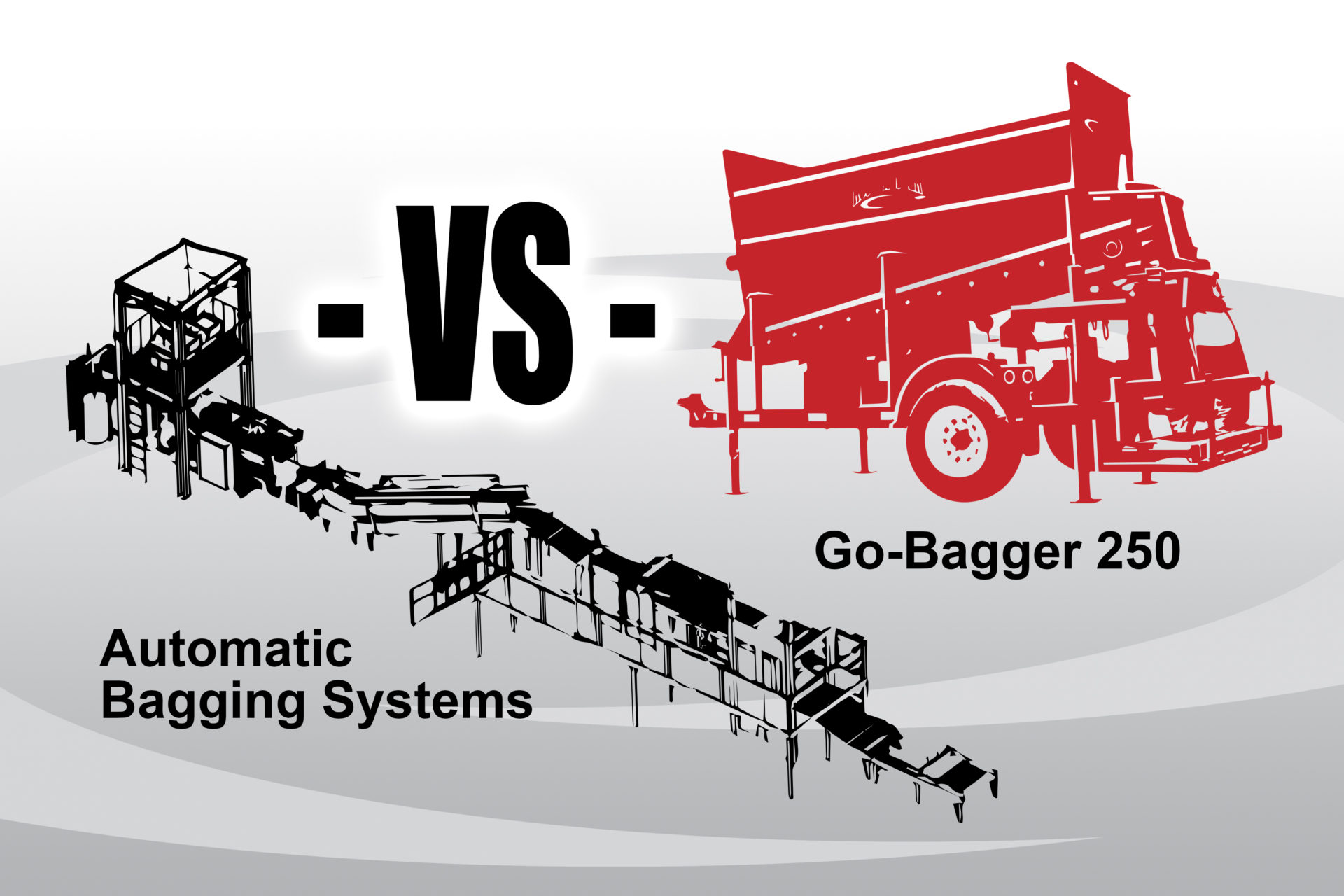

In Part 1 of this series, we looked at the basic design and capabilities of the Rotochopper Go-Bagger® 250. Now in Part 2 we’ll compare the Go-Bagger® 250 to larger, automatic bagging systems. Part 3 of this series will compare the Go-Bagger® 250 to the smaller product-specific bagging systems on the market. The goal is to compare general categories of baggers, rather than specific brands and bagger models. If you’re in the market for a bagging system, you have a range of choices. With some careful research, you can find an equipment solution that matches your products, volume requirements, operating environment, and budget.

Part II: Go-Bagger® 250 VS Automatic Bagging Systems

Form-fill-and-seal systems are designed for high production with minimal labor. If you want to pound out 10,000 bags a day, you’re in the market for a form-fill-and-seal system. If you’re looking for 10,000 bags per week or less, the Go-Bagger® 250 may be a good fit. The Go-Bagger® 250 will fill and seal 200 – 750 bags per hour depending on the product, number of operators, and other factors. You can easily find a handful of automatic bagging systems that will reliably fill dozens of bags per minute—much more than the Go-Bagger® 250 is capable of bagging. Many of these systems will palletize bags then shrink wrap the pallet and bags. They are very intricate and interesting to watch, but they are not for everyone.

Limitations of Automatic Bagging Systems

Limited Flexibility

Automatic baggers often lack the flexibility to quickly switch between different products and bag sizes.

Complexity & Extended Downtime

Because they are complex systems, downtime may be lengthy and costly if problems occur.

Large Footprint

An automatic bagger typically has a large footprint and requires a fully enclosed building with 3-phase power. They are usually limited to stationary operation by nature of their design.

Difficulty with Wet, Sticky Materials

Because form-fill-and-seal baggers are designed for maximum automation, they often have difficulty handling irregularities. For example, wet, sticky products like compost may clump together and bridge up in conveyors and chutes. If you want to purchase an automatic bagging system for a product like compost, make sure it has equipment to break apart compacted material into a smooth flow.

Further Research

If you are interested in a high volume automatic bagging system, use the generalizations above as starting points for your research, not as conclusions. You will find exceptions to every statement made above about the limitations of automatic bagging systems.

Summary of Automatic Bagging System Requirements

If your business and bagging needs meet the following criteria, a form-fill-and-seal system may be a good fit:

- Centralized location

- High volume requirements (thousands of bags per day)

- 3-phase power

- An enclosed building to accommodate a large footprint

If your business lines up with the bullet points above, particularly the need for high production, you can find some very well built automatic bagging systems to fit your needs.

Narrowing Your Choices

After you narrow your options based on the criteria above, start with a process of elimination. Focus only on the bagging systems that you know will (1) handle your raw materials and (2) meet your production needs.

Conclusions

There are some really good automatic bagging systems on the market. But if your bagging requirements fall outside the target market for automatic bagging systems, start looking at smaller or more flexible baggers. We will cover smaller bagging system in part 3 of this series, which compares the Go-Bagger® 250 to product-specific baggers.

Learn More

If you have questions about retail bagging markets and the Go-Bagger® 250, feel free to contact us today. Your regional Rotochopper representative is an expert in value-added commodity markets like landscape mulch, compost, and animal bedding.