Choosing the best new grinder for your fleet can be difficult. A grinder that doesn’t suit your current workflow may require significant downtime and offer limited benefits to your operation, while the ideal grinder will integrate seamlessly into your existing workflow with minimal interruption.

There are several factors to consider when choosing an industrial horizontal grinder, but the following four considerations are among the most important to making a sound addition to your equipment fleet.

Electric Grinders vs. Diesel Grinders

Grinders are available in both electric and diesel varieties. The type of grinder that’s best for you will depend on factors such as fuel and electricity costs, the environmental impact of the grinder, and portability.

Electric grinders require access to 3-phase power, necessitating a stationary or semi-portable operation. The cost of electricity remains relatively stable, meaning electric grinders aren’t subject to the fluctuation of diesel prices. Diesel grinders, in contrast, offer portability, especially when paired with our track and dolly system. These grinders also require the upkeep associated with traditional diesel engines, including oil and filter maintenance.

For more information on choosing between an electric and diesel grinder, check out our blog here.

Particle Size and Versatility

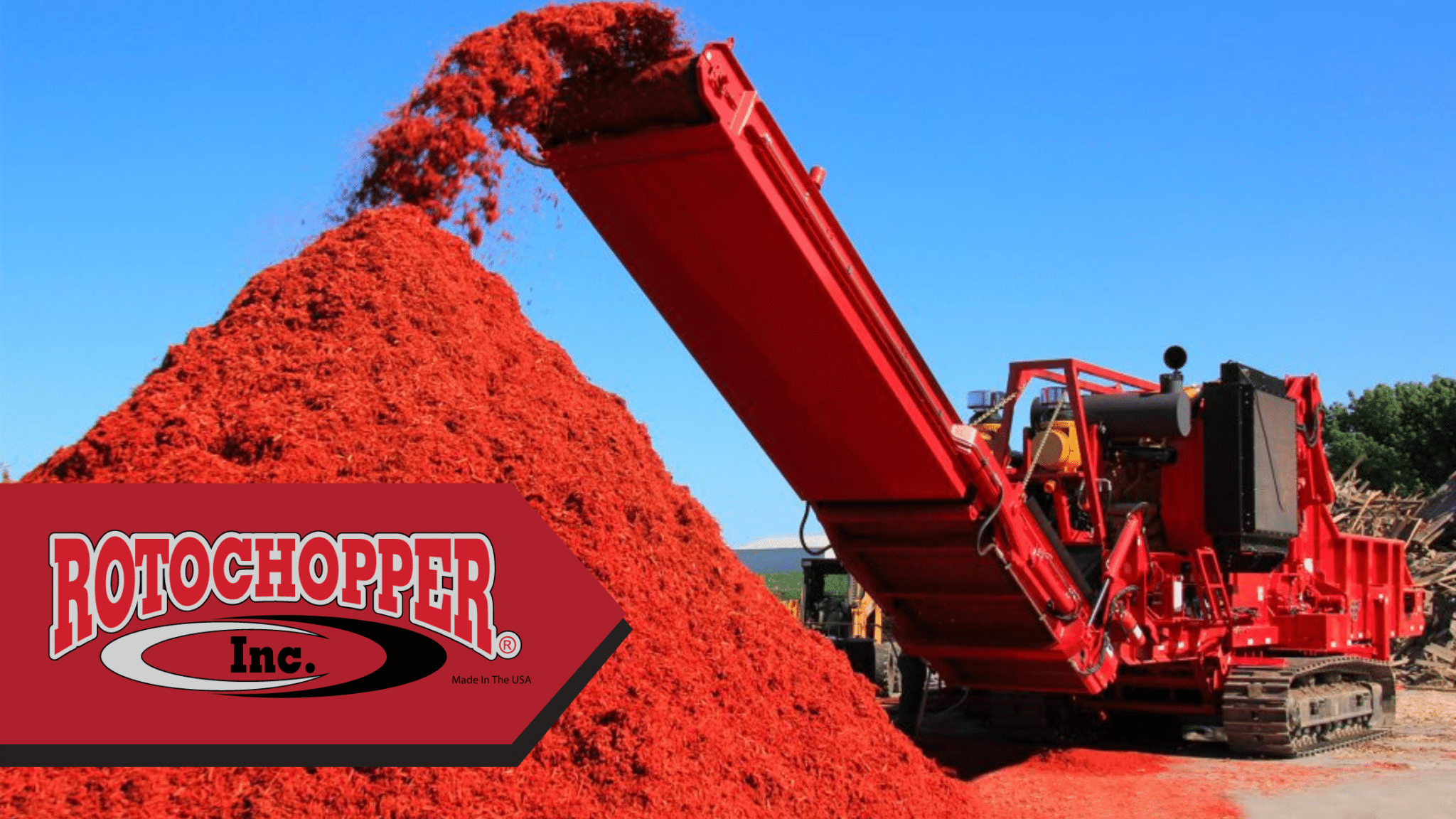

Grinders will produce different particle sizes depending on horsepower, teeth style, screen size and type, and more. When choosing an industrial grinder for your fleet, consider the end product size demands of your industry. Rotochopper’s “Perfect in One Pass”® technology produces a wide range of end products at the precise size you need them.

This high level of grinder customization provides your operation with ample versatility and new opportunities within—and beyond—your industry. With the ability to grind different types of feedstocks to different sizes, your operation can produce multiple, profitable end products and create new sources of revenue.

Safety Features

Grinding can be dangerous, especially if pieces of metal or other hard substances enter the grinding chamber. Safety features should always be a top priority for those looking to add to their fleet. Rotochopper grinders have a range of safety mechanisms to protect your employees and equipment, mitigate downtime, and remove ferrous metals.

Rotochopper grinders make use of our proprietary StopWatch vibration monitoring system. When an object that can’t be ground enters the grinding chamber, the StopWatch system senses the spike in vibration, automatically stopping and reversing the infeed conveyer, which not only prevents the object from being ejected but also protects the grinder itself from damage.

Rotochopper horizontal grinders are also equipped with our shear bolt damage protection system. The screens of our horizontal grinders are held in place with cam arms and shear bolts. When a significant impact with an ungrindable object occurs, the bolts shear, allowing the screen, slab ramp, and cradle to fall away, limiting damage and fire hazards from sparking.

Supporting Equipment

When choosing a horizontal grinder to add to your operation, you’ll also want to consider how well the grinder gels with your existing workflow. All of Rotochopper’s horizontal grinders, screening equipment, and conveyors are designed to seamlessly integrate into existing waste reduction systems, but the specific grinder model that works best for you will depend on your operation’s workflow.

Talk to a Rotochopper sales representative to find a grinder that complements and completes your existing operation.

Contact Rotochopper to Discuss Horizontal Grinders for Sale

Determining the best grinder for your fleet starts with identifying your operation’s needs and the specifications of your existing workflow. Nobody knows your operation better than you, putting you in the best position to select a horizontal grinder with the portability, efficiency, and sizing capabilities you need.

Rotochopper offers a range of safe and efficient horizontal grinders and supporting equipment capable of boosting your workflow’s safety, productivity, and efficiency. Contact us to learn more about the diesel and electric horizontal grinders we have for sale worldwide.