As the global demand for renewable energy continues to rise, wind power has become one of the leading sources of clean electricity. With thousands of wind turbines operating worldwide—and many reaching the end of their service life—the industry now faces a new challenge: windmill blade recycling.

Wind turbine blades, often stretching over 170 feet long, are made from a complex mix of fiberglass, carbon fiber, thermoset resins, and balsa wood. The same resilience that allows these durable structures to withstand years of wind, rain, and sun makes them notoriously difficult to recycle.

Traditional waste management systems can’t process blades efficiently due to their size, strength, and chemical makeup. As a result, wind turbine blade disposal often means cutting blades into smaller pieces and sending them to landfills. Not only is this a costly practice, but windmill blades are created to last—meaning their materials will last centuries before breaking down.

With decades of experience designing heavy-duty horizontal grinding and shredding equipment, Rotochopper helps recycling companies and renewable energy operators turn wind power waste into new opportunities through efficient and sustainable recycling processes.

The Role of Size Reduction in Windmill Blade Recycling

Before windmill blades can be reused, transported, or disposed of, they must first be reduced in size. These enormous, rigid structures can’t be fed directly into recycling machinery or easily hauled away, which makes shredding windmill blades the essential first step in any recycling operation.

By breaking blades down into manageable pieces, recyclers can sort, separate, and prepare the composite materials for secondary processing. This may include grinding, incineration for energy recovery, or incorporation into new materials like cement additives or construction composites.

When it comes to size reduction, equipment selection matters. Slow-speed shredders and high-speed grinders each play unique roles. High-speed grinders are excellent for producing uniform, fine materials, but they can struggle with dense, fibrous materials like fiberglass-reinforced resin. Slow-speed shredders, on the other hand, are designed for heavy-duty cutting. Their low RPMs and high torque make them ideal for breaking down tough materials without excessive wear or heat buildup.

Within the field of windmill blade recycling, slow-speed shredders also excel at minimizing maintenance costs, preventing damage from foreign materials, and delivering consistent throughput. They efficiently prepare blades for downstream processing—whether that’s transport, grinding, or reintroduction into new manufacturing cycles.

How Rotochopper Serves the Wind Turbine Blade Disposal Industry

At Rotochopper, we’ve earned our reputation as a leader in wind energy waste management by engineering machines that thrive in demanding applications. From horizontal grinders to slow-speed shredders, conveyors, and screening equipment, we offer complete systems that streamline the recycling of even the toughest materials—like wind turbine blades.

Each piece of Rotochopper equipment is designed to integrate seamlessly into a continuous workflow. For example, shredded blade material can move directly from our 95DK Slow-Speed Shredder to a horizontal grinder for further refinement, with conveyors and screening systems ensuring smooth material handling and consistent sizing.

This integrated approach reduces downtime, improves safety, and optimizes material flow—helping recyclers maximize productivity and sustainability. Whether processing windmill blades, railroad ties, or other composites, Rotochopper’s systems help operators turn waste into valuable raw material.

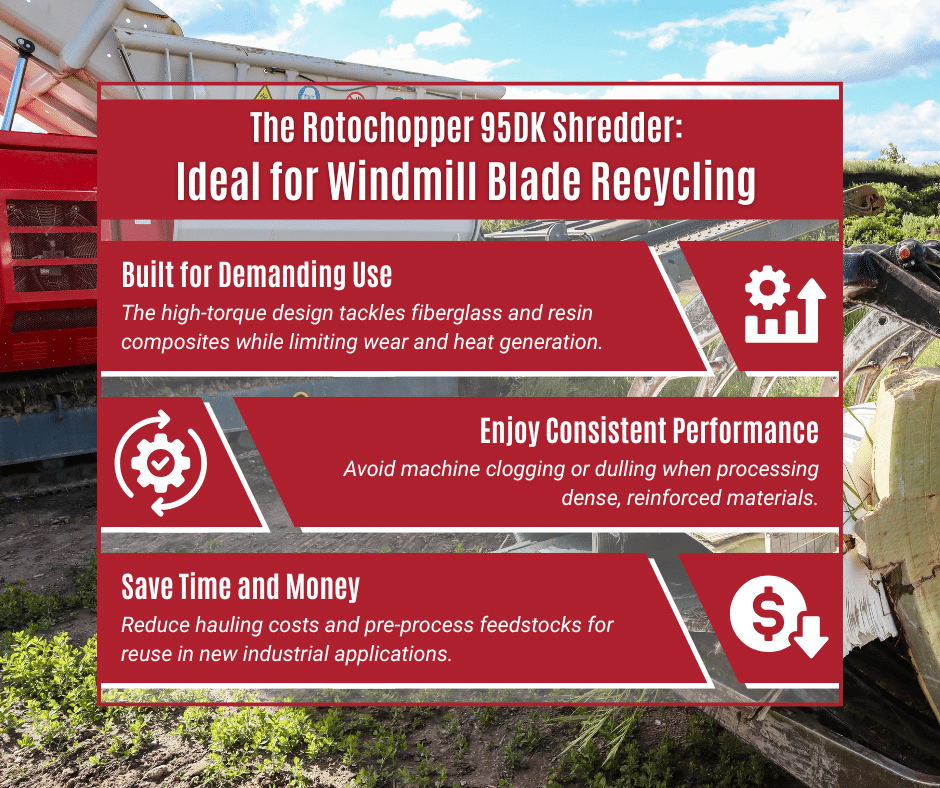

The Rotochopper 95DK Shredder: Ideal for Windmill Blade Recycling

At the heart of Rotochopper’s windmill blade recycling solutions is the 95DK Shredder—a powerful machine built to tackle your toughest materials.

The 95DK’s high-torque design and twin-shaft cutting system allow it to tackle fiberglass and resin composites while limiting the wear or heat generation that can occur with high-speed grinders. This not only extends the life of the teeth but also reduces energy consumption and maintenance costs.

While high-speed grinders can clog or dull quickly when processing dense, reinforced materials, the 95DK Shredder maintains consistent performance under extreme loads. With variable speed control, robust construction, and exceptional torque, it delivers a throughput rate capable of handling full-scale wind turbine blade disposal operations.

In the field, Rotochopper customers have reported significant time savings and reduced operational costs by using the 95DK to pre-shred windmill blades before further processing. By producing uniform, transportable chunks, recyclers can reduce hauling costs and prepare materials for reuse in new industrial applications.

The Next Steps in Windmill Blade Recycling

While shredding windmill blades is a crucial part of the process, the journey doesn’t end there. Researchers and manufacturers are exploring innovative end-use applications for shredded blade material—such as reinforcing concrete, producing composite decking, or manufacturing new turbine components.

As the industry continues to evolve, Rotochopper remains a trusted partner in innovation. Our commitment to sustainable recycling and adaptable equipment ensures that customers are ready to meet the next challenge in wind energy waste management, and our team is dedicated to helping customers make the most of every opportunity.

Partner with Rotochopper to Turn Waste into Opportunity

With durable, high-performance equipment and unmatched customer support, Rotochopper empowers the renewable energy industry to take the next step toward a cleaner future.

To learn more about Rotochopper’s complete line of shredders, grinders, and integrated systems, find a sales rep in your area.