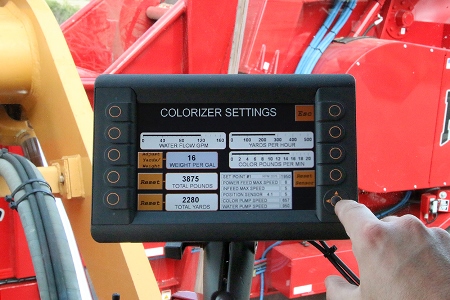

Managing grinder operating costs has never been easier or more effective thanks to the new Rotochopper remote monitoring and control system. Tracking production rates and input materials (such as water and mulch colorant) in real time helps ensure a uniform finished product at the lowest cost per cubic yard or ton.

This system puts real-time monitoring and adjustment capabilities right into your loader cab or onto your office desk. Not simply a wireless remote, this wireless interface puts the functionality of

the main operator control station at your fingertips anywhere within wireless range of your grinder.

Live Data & Adjustment

Best of all, this remote interface provides a greater level of data and control than a typical grinder control system.

Live data and adjustable parameters include:

- Throughput rate

- Colorant application rate

- Water application rate

- Rotor vibration levels

- Infeed conveyor speed

- Powerfeed roller speed

- Powerfeed max position

- Powerfeed crush / flotation pressure

- Slab ramp position (for optional hydraulically actuated slab ramp)

- Engine RPMs and other data

- Clutch status

Some types of data require additional monitoring equipment; ask your Rotochopper representative which monitoring options are right for your raw materials and finished products.

Remote monitoring systems are available for Rotochopper electric wood grinders, diesel wood grinders, shingle grinders, and multi-stage grinders.

Complete Control. Completely Simplified.

Now you can match grinder settings to a new feedstock without leaving your loader cab and analyze production costs right at your desk. Minimizing the costs of premium fiber products like animal bedding and colored landscape mulch has never been simpler.

Learn More

How can a Rotochopper remote monitoring and control system streamline your grinding operation. Contact us today to learn more.