Throughout our 35-year history, Rotochopper has stayed true to our mission to provide high-quality, reliable waste management solutions to our customers. Driven by our spirit of innovation, we leverage detailed customer feedback and real-world performance data to engineer durable, robust horizontal wood waste grinders that tackle tough jobs without sacrificing operational efficiency.

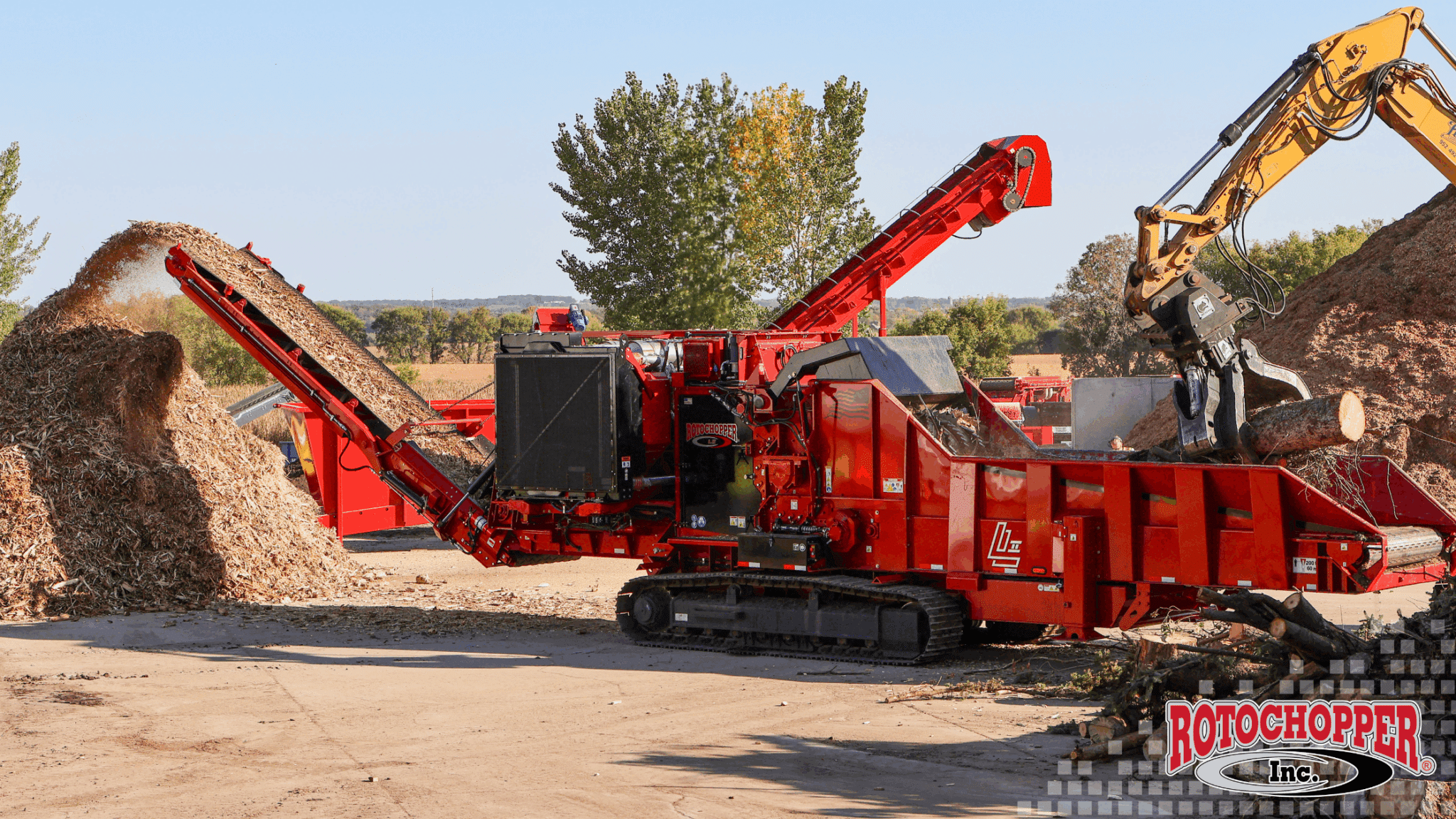

Rotochopper is proud to introduce our new diesel horizontal grinder: the L II. The newest addition to our diesel grinder lineup, the L II was designed to take on the toughest feedstocks in the waste management industry. Its rugged design and high-performance engine make it the ideal choice for job site grinders that need to quickly process large volumes of abrasive wood feedstocks, including tree stumps, yard waste, whole trees, and construction debris. As Rotochoppper President and CEO Tosh Brinkerhoff puts it: “The L II is a game changer for Rotochopper. We have taken direct customer feedback to develop a heavy-duty machine that is not only durable, but is more reliable, easier to operate, and will process tougher material in less time.”

Features of the L II Horizontal Grinder

In addition to an extensive list of standard features, the L II offers a combination of raw power and intelligent design features—enhancements that make it uniquely suited to the most demanding jobs.

Single Pivot Powerfeed

The L II boasts a single pivot powerfeed. Not only can the grinder’s opening accommodate larger and tougher material, like whole trees and dense brush, but the powerfeed itself is aggressively angled to make tough job smoother. With the L II’s single pivot design and powerful engine, operations can streamline their most challenging wood waste grinds with a controlled, even feed of material while supporting safer operations.

Rotor Configurations

During the development of our newest horizontal grinder, Rotochopper engineers also expanded our customers’ options for rotor configurations. The L II is compatible with all existing rotor configurations, as well as our newest design, which features a weld-on mount. With an array of options to match your operation’s needs, speaking with a Rotochopper sales representative is the best way to find the configuration that suits your workflow, feedstock, and job site grinder requirements.

Up to 1,200-Horsepower

The L II wood waste grinder is offered with up to a 1,200-horsepower engine. “One of the most impressive features of the L II is its additional horsepower,” says Rotochopper customer Ryan Williams of GreenGo Recycling, LLC in South Carolina, who tested the machine at his site. “What I mostly love about the L II is just that sheer power….This machine is equipped with a C32 CAT engine, providing significant power. Given the huge logs that often come into our facility, the increased horsepower of the L II has been invaluable in helping us efficiently process and chew through large volumes of material.”

High-Wear Infeed and Liners

Built with an incredibly durable belt and substructure, the L II was designed to resist wear for longer service life, less downtime, and consistent performance. With replaceable, bolt-in liners that can be configured to process a range of materials, the L II protects high-impact zones against the toughest feedstocks for consistent grinding power.

18” Ground Clearance

The L II also features higher ground clearance, making the diesel grinder ideal for tough, uneven terrain.

Thicker Screens

In addition to our patented screen change system, the L II offers 15% more open surface and one-inch-thick screens to tackle tougher materials without sacrificing productivity.

Enhanced User Controls

This addition to our grinder lineup is also the first piece of Rotochopper equipment to use our updated digital interface, featuring smarter diagnostics and more control. “It’s just so easy with the controls, just to get [it] up and running in an instant,” Williams says. “…Our operator really loves…the integration between the computer system and his control. It pretty much runs itself.”

RotoLink® comes as a standard feature on this machine. With RotoLink, operators can measure their results with real-time telematics, optimize their workflow with remote access, and get on-demand support from Rotochopper’s world-class service team.

Use Cases of the L II Job Site Grinder

Industries facing high-capacity production needs or tackling abrasive feedstocks can benefit from the L II’s efficiency, flexibility, durability, and raw, rugged power. In particular, the diesel grinder’s aggressive infeed and rotor configuration options make it ideal for the tough feedstocks and terrain inherent to the land clearing industry. In a broader sense, the L II’s increased horsepower helps any large wood waste grinding operation process larger amounts of material in the same amount of time.

Streamline Your Operation with the L II Diesel Grinder

At Rotochopper, we know our success is defined by our customers’. The L II was created with direct feedback from real customers, and it is thanks to them that we can continue to provide superior grinding solutions to operations all over the world.

To find out if the L II diesel grinder is right for your operation, or to find the wood waste grinding equipment that meets your waste management needs, speak to a Rotochopper sale representative today.