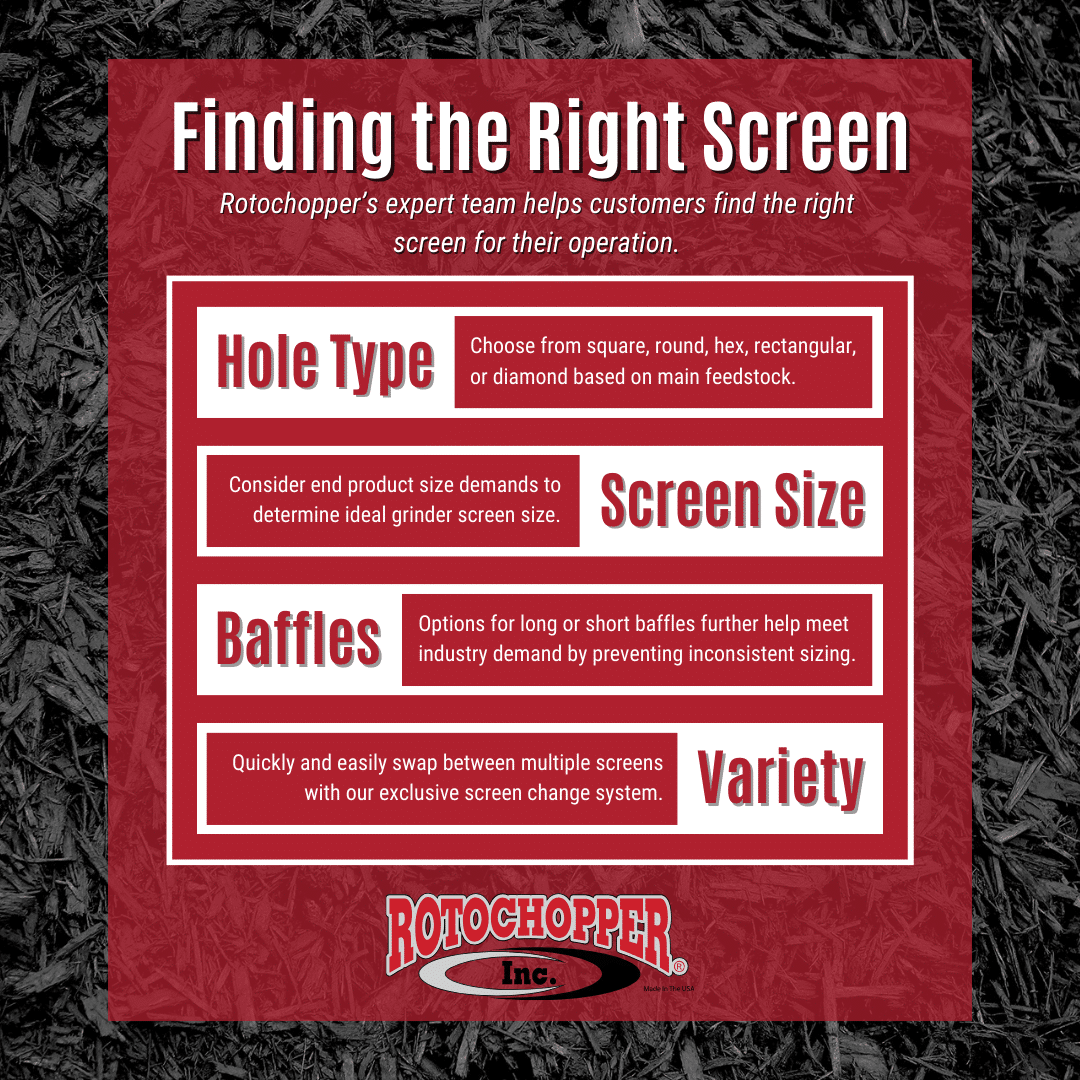

A successful operation relies just as much on its equipment as it does its people, and grinder screens are among the most important pieces of equipment on the worksite. Horizontal grinder screens vary in terms of screen shape and opening size. At Rotochopper, we offer a variety of grinder screen types to meet every industry need, as well as a exclusive screen change system designed to minimize your operation’s downtime when it comes time to change screens.

How Horizontal Grinder Screens Impact Your Operation

Matching screen specifications to your feedstocks’ “sweet spot” allows you to optimize your operation and boost efficiency while improving the consistency and quality of your end products. For products with strict end-product dimensions, Rotochopper’s diverse range of grinder screens also ensures operators can easily produce the end product they need at the size the industry demands.

Common Horizontal Grinder Screen Types

With Rotochopper’s exclusive screen change system, 15 minutes is all it takes for operators to switch between screen types, allowing them to grind different feedstocks and produce different end products. Our B and FP model grinders can be equipped with two different screens, providing operations with further versatility to meet the needs of their application. In addition, Rotochopper’s damage mitigation systems keep screens, no matter the type, in good condition by allowing the screen to fall away from material when struck by a large, un-grindable object.

With over 30 years of experience in the waste reduction industry, Rotochopper has manufactured and refined our horizontal grinder screens to meet our customers’ needs. As a factory-direct company, our service team and demo technicians have the in-depth knowledge needed to help you choose the right screen, or screens, for your operation.

Square

Square screens are the most common horizontal grinder screen type and are ideal for woody materials, like pallet waste and C&D debris. They provide remarkably consistent material sizes but may result in varied material lengths.

Round

Round screens work best for grinding soft-to-hard woods with normal moisture levels. They are ideal for achieving a fine grind. Round hole screens normally work well to produce playground matting because the finished grind has softer edges.

Hex

Hex screens are most popular as an alternative to round screens and allow for more screen openings in the same amount of space. Along with diamond screens, hex screens are popular with mulch producers.

Rectangular

Like hex screens, rectangular screens allow more feedstock to pass through the grinder at a time, boosting production. However, consistency can be an issue for them, and material ground with a rectangular screen may need to be re-ground later.

Diamond

Diamond screens are ideal for fibrous, stringy, and wet material like compost, damp grass, and leaves. This screen channels materials in such a way that the cutter pinches off the material, avoiding accumulation and clogs around the screen.

Screen Baffles

Rotochopper customers have the unique option to add short or long baffles to their horizontal grinder screens, which can help prevent inconsistent sizing. The baffles are welded to the screen and keep long spears from exiting the screen holes, resulting in a more uniform product.

End Product Sizing Based on Industry

It’s important for operators to understand the sizing requirements of their industry before choosing a grinder screen, as improper sizing can drive up costs and waste both time and resources.

Compost

Compost should be ground to a consistent size under four inches. Anything larger could compromise the material’s ability to break down in the environment.

Mulch

The ideal size for ground mulch is two-and-a-half inches, but it can go down to as small as one inch. Mulch size preference can vary by region across North America. Consistency is important, especially in the mulch industry, and poorly ground mulch can significantly impact sales.

Biomass/Biofuel

Biomass produced with grinders must meet strict sizing requirements to ensure the end product can be used in biomechanical processes. Biomass that is too large may not react correctly to outside stimulation, making it practically useless.

Find the Best Screen for Any Operation with Rotochopper

Rotochopper strives to provide our customers with the best quality horizontal grinder screen options on the market. Contact us to learn more about our horizontal grinder screens and our expert team will help you find the right ones for your industry.