In an era where innovation intersects with sustainability, Rotochopper is revolutionizing the way industries approach waste management and recycling. In keeping with our steadfast commitment to efficiency and environmental stewardship, we offer a range of machines designed to seamlessly integrate into existing grinding systems and produce fine-textured end products with minimal emissions, including our RMT Hammermill.

The RMT Hammermill is a fine-grinding system that can be configured to work in tandem with a Rotochopper grinder or designed to work with a feed hopper as a stand-alone product to produce quality end products in a single pass. By turning waste into valuable secondary products or reducing its volume to minimize disposal costs, the RMT Hammermill exemplifies Rotochopper’s dedication to providing complete grinding solutions that meet the diverse needs of businesses in a variety of industries.

The RMT Hammermill in Action

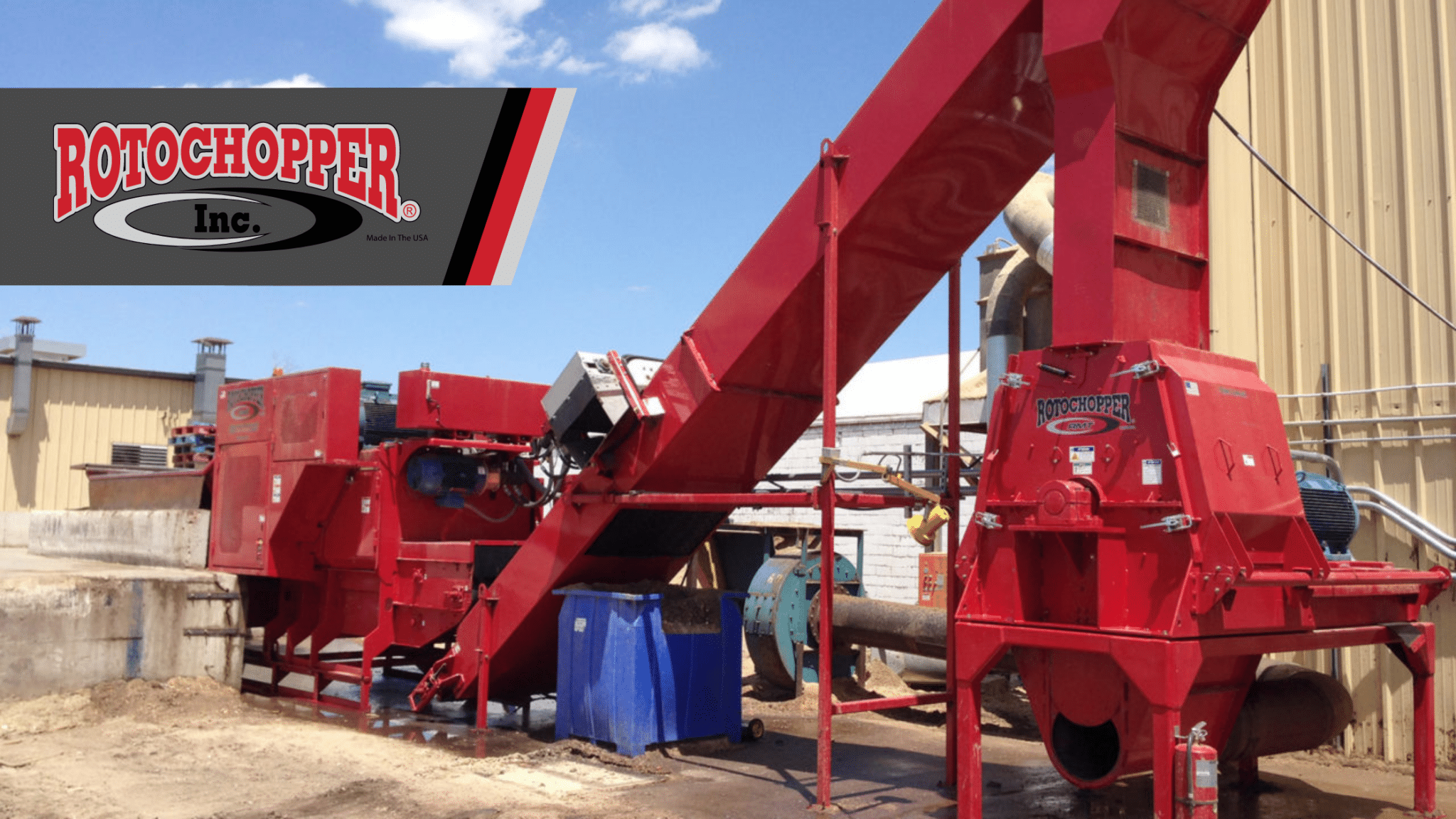

The RMT Hammermill is engineered to operate as part of a two-stage grinding system alongside Rotochopper’s B-66E grinders and EC model grinders or as a stand-alone unit with a feed hopper, producing ultra-fine textured end products, such as high-quality animal bedding and biomass.

The modular nature of this process allows the hammermill to scale its production to meet the needs of the worksite, streamlining production and opening up new market opportunities by enabling the creation of multiple specialized end products with the same system.

How the RMT Hammermill Operates

Precision lies at the core of the RMT Hammermill’s design. Materials enter a robust metal drum, housing a rotor adorned with tungsten carbide hard-faced hammers, renowned for their durability and impact resistance. As the rotor spins at high speeds, these hammers exert force on the feedstock, pulverizing it into fine fragments. These particles are then funneled out of the mill, ready for use as end products or for further processing.

Transforming Waste into Revenue

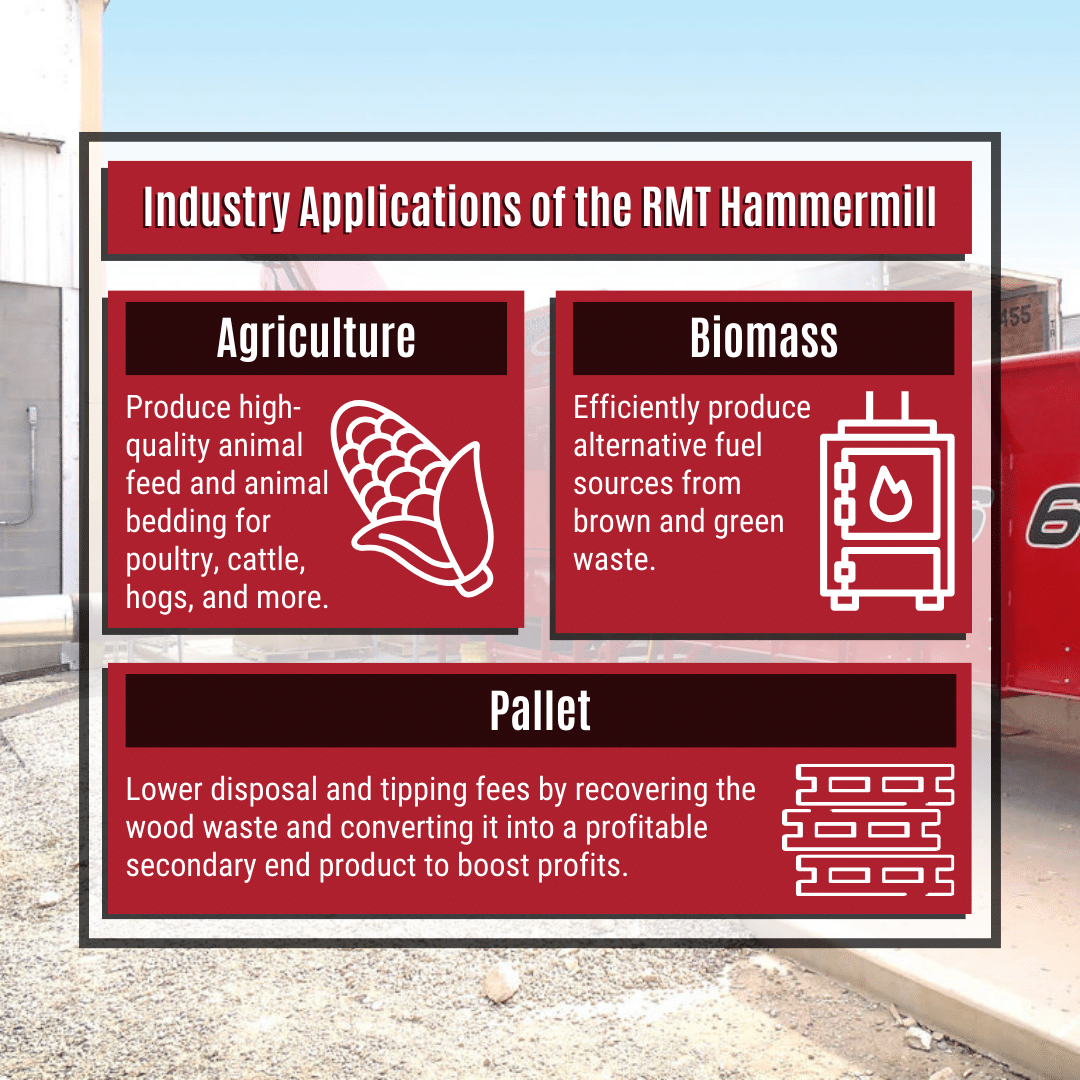

As a short fiber product grinder, the RMT Hammermill enables businesses in a range of industries to reduce, reuse, or recycle their waste. In many cases, businesses may even be able to convert their waste into profit. As an integral part of a precision grinding system, the RMT Hammermill is exceptional at producing fine end products, including premium animal bedding, animal feed, fuel pellet stock, and other short-fiber products from industrial waste.

By efficiently converting these materials into valuable commodities, the RMT Hammermill exemplifies Rotochopper’s commitment to sustainability and profitability. It enables worksites to not only reduce waste but also to tap into new revenue streams by catering to the growing demand for eco-friendly products.

Customizing Your Rotochopper Hammermill System

The RMT Hammermill boasts several features that place it a cut above other short fiber product grinders. A notable advancement is the introduction of our enhanced 600 HP model, designed to tackle higher volumes of feedstock and achieve greater production rates, meeting the needs of operations looking to scale up their output. Additionally, our bi-directional mill ensures that wear is evenly distributed, reducing maintenance costs and significantly extending the lifespan of the machinery.

If your operation frequently tackles contaminated wood waste, the RMT Hammermill can also be equipped with a S-chute magnet to remove metal, producing a cleaner end product.

At Rotochopper, we offer customizable hammermill systems to ensure you find the size and model that meets your operation’s unique requirements. By collaborating with a Rotochopper sales representative, businesses can tailor their equipment with additional features like specialized hoppers and conveyor systems to optimize feeding processes.

Optimize Your Efficiency with Rotochopper

The Rotochopper RMT Hammermill epitomizes Rotochopper’s dedication to addressing the diverse needs of the waste processing and recycling industry. Its ability to produce fine, valuable end products from waste materials not only showcases Rotochopper’s commitment to sustainability but also opens new market opportunities for businesses across various sectors.

With customizable features, enhanced durability, and factory-direct support, Rotochopper’s solutions are designed to meet the evolving needs of almost any industry, empowering businesses to transform waste into profit with unparalleled efficiency.

Contact Rotochopper today to learn more about the RMT Hammermill.