Horizontal grinding equipment is built to weather the demands of industries ranging from organic waste recycling and pallet demolition to logging and land clearing—but over time even the sturdiest equipment can falter. Eventually, your operation’s equipment will need to be retired and replaced.

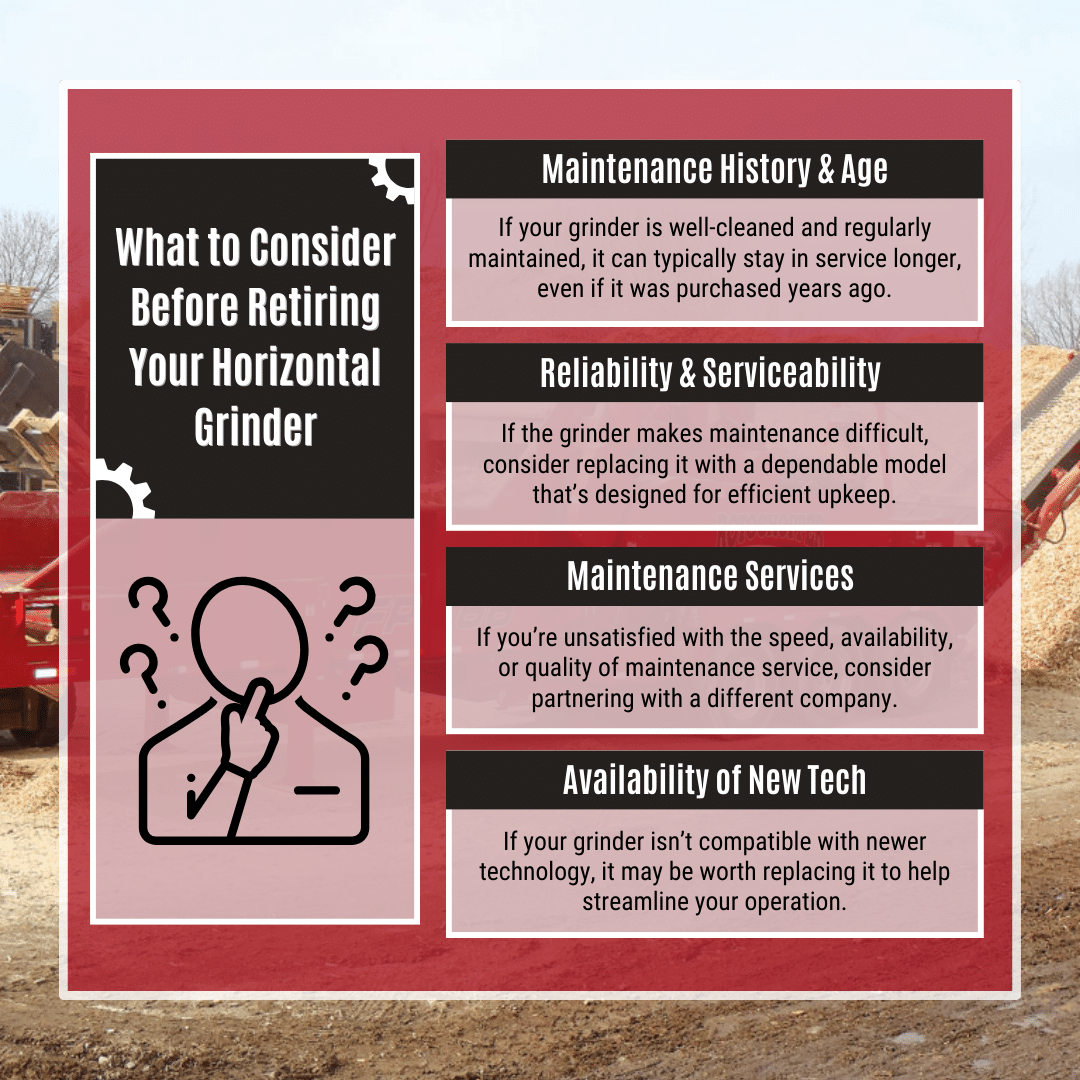

The best time to retire your equipment depends on several factors, including the age and condition of your machine, access to service expertise through the manufacturer, and your company’s operational goals.

When to Retire a Machine

Retirement and replacement aren’t necessarily the best options for every machine—maintenance may be all that’s necessary to get your horizontal grinding equipment back in peak shape. When deciding whether to retire your equipment, consider factors like equipment history, reliability, and serviceability.

Maintenance History and Grinder Age

When considering grinder replacement, your machine’s age matters—but its maintenance history is equally if not more important. Regularly cleaned and well-maintained machines can be kept in service far longer than poorly maintained grinders, which may cost more to repair than to replace. Similarly, regularly replacing wear parts as necessary can significantly extend the longevity of the machine. Horizontal grinders that undergo periodic part replacements over their lifespan often remain operational for years, as this practice minimizes the machine-wide impact of worn components.

Reliability and Serviceability

Reliability and serviceability vary across horizontal grinder brands. Some companies produce equipment using complicated proprietary systems or specialized parts that make servicing the equipment tedious, while other manufacturers—like Rotochopper—produce reliable equipment that’s designed with repair efficiency in mind. If you’re unsatisfied with your equipment’s serviceability, it may be time to retire your grinder and replace it with a model from a more dependable brand.

Manufacturer Maintenance Services

Closely related to your machine’s serviceability is the availability and quality of the service. Many horizontal grinder manufacturers offer first-party maintenance programs designed to keep their grinders in service for as long as possible.

Rotochopper offers a comprehensive preventative maintenance program to help operators stay on top of wear part replacement, prevent large breakdowns, and train employees on best operational practices. If you’re considering retiring your machine, a preventative maintenance program may help prolong its lifespan and may be a more cost-effective solution than replacement. However, if your horizontal grinder is truly ready to retire, a preventative maintenance program is still a key investment to maximize the lifespan of its replacement.

Availability of New Grinder Technology

Even if their horizontal grinder isn’t at the end of its life, operators may accelerate the retirement timeline if they find a model that better meets their operational needs. Depending on when your original grinder was built and which manufacturer built it, it may not be compatible with newer horizontal grinder technology—technology that could greatly improve operational efficiency. If your primary feedstock or another core aspect of your operation has changed since you bought your first machine, work with a horizontal grinding expert to find a model that’s compatible with the technology you need.

Rotochopper boasts a diverse selection of industrial horizontal grinders that come standard with innovative features. These include Rotochopper’s patented screen change system, which allows operators to switch between different screens and feedstocks with minimal downtime, and the StopWatch system, which helps prevent damage from un-grindable objects. We also offer a variety of optional features to enhance your operation, like our onboard colorizer, our remote monitoring system RotoLink®, and our track and dolly system.

Partner with a Factory-Direct Partner

With over three decades of expertise, Rotochopper is always working to further improve our equipment based on real customer feedback. Our industrial horizontal grinders are equipped with the most advanced features on the market—from aggressive powerfeed systems to our proprietary remote monitoring system. Our commitment to providing comprehensive solutions, coupled with our preventative maintenance services, makes us an invaluable partner for operators looking to make the most of their equipment.

When you partner with us, rest assured you’re working with a true expert in the industry. Contact Rotochopper today to explore your options for horizontal grinder replacement.