Horizontal Grinders vs Whole Tree Chippers

While both chippers and grinders effectively process wood waste, the machines differ in their ability to grind feedstocks to different sizes. To find the equipment that works best for their operations, project managers and business owners should understand the difference between whole tree chippers, horizontal wood grinders, and horizontal grinders with conversion packages.

| Whole Tree Chipper | Horizontal Grinder | |

| Raw Materials | Logs and small, round wood. | Logs, whole trees, brush, forestry residue, sorted C & D, pallets, waste, agricultural products, and shingles. |

| Efficiencies | Processes clean round wood quickly. | Requires more horsepower to turn waste wood into chips. |

| Versatility | Only used for chipping clean, round wood. | Used for a variety of applications by switching teeth and screens. |

| End-Product Control | Product size controlled by the number knives in/on the chipper drum. Fewer knives mean less control over product size, while more knives mean more control over product size. | Product size controlled by screens and teeth. |

| End Products | Chips, micro-chips, sawdust. | Chips, mulch, colored mulch, playground cushion, fine-texture fiber, and compost. |

| Uptime and Maintenance | High wear costs and frequent down-time. Raw material must be clean to ensure consistent uptime. Contaminants quickly damage the chipper knives, and rotors need to be swapped to change applications. | Replaceable mounts can be switched quickly and by a single operator. Indexable knives can be reversed when they become dull on one side. No specialized tools are required to switch applications. |

Whole Tree Chippers

If you have a steady stream of clean round wood, nothing beats the efficiency of a chipper. Whole tree chippers are designed for a single purpose—to quickly process solid, round wood—and they do it better than any other machine on the market.

Many industries need chips produced by a whole tree chipper, including paper manufacturers, companies that use particle board, and certain fuel industries. Some chippers produce highly uniform chips, while others produce short fiber chips for pellet fuel production and other applications. Some chippers even feature a screen to help maintain uniform chip size.

Types of Whole Tree Chippers

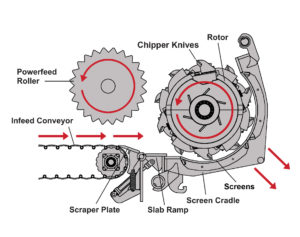

There are two kinds of whole tree chippers—disc chippers and drum chippers. Disc chippers consist of a large disc that uses sharp steel knives to cut wood perpendicular to the surface of the disc. A drum chipper consists of a large drum that uses steel knives to cut wood and propel chips into the discharge chute.

Disc chippers produce precisely sized chips that are good for pulp and paper, but they do not produce chips at a high volume. Drum chippers are better equipped to produce chips that will be used for pellets or biomass fuel. With both systems, the end product size can be altered by changing the size and number of the drum or disc knives.

Whole Tree Chippers Maintenance and Wear Costs

Chippers often involve high wear costs and frequent downtime, especially in environments where operators have little control over contaminants. Sand, dirt, rocks, and steel can quickly cause expensive damage that may be time-consuming and costly to repair, further costing your operation valuable uptime.

As knives become dull or damaged, particle size will usually increase and become inconsistent. Knife dullness can occur within just a few hours—if they encounter an ungrindable object, like a rock, they can be dulled almost instantly. Additionally, if pliable or small-diameter branches bend or twist in the throat opening, they can pass through a chipper as long spears, rather than chips.

Whole tree chippers also generally have difficulty feeding and chipping material of mixed dimensions, including tangled piles of tree trunks and branches. Many chippers lack a feed system aggressive enough to process whole trees with rigid limbs.

In general, once you move outside a wood chipper’s design purpose, its advantages over a wood chip grinder quickly disappear.

Horizontal Grinders

Whereas chippers are highly specialized, horizontal grinders boast increased versatility, allowing operators to easily switch feedstocks by swapping rotors, screens, and teeth. Wood chip and mulch grinders are flexible enough to switch between processing logs, whole trees, bark, slab wood, and other solid materials while maintaining precise end-product control. Horizontal grinders can also efficiently process green wood, seasoned timber, or kiln-dried lumber, including pallet waste and sorted C & D.

Horizontal Wood Chip Grinder Options

The customizability and versatility of horizontal wood chip grinders mean they can easily be converted into chippers. There are several ways to convert a grinder into a chipper, the easiest of which is by installing a chipper conversion package.

Horizontal Grinder with Chipper Conversion Package

Pairing your horizontal grinder with a chipper conversion package reduces wear costs and maximizes your operation’s uptime by allowing fast, convenient access to teeth and screens.

If your operation needs to perform across multiple applications, utilizing a mulch grinder is the way to go. If your operation’s only end product is wood chips, a whole tree chipper will always outperform a horizontal wood chip grinder with higher production rates and efficiency.

The Rotochopper Advantage

A Rotochopper horizontal grinder makes chipping and grinding easy with versatility across use cases, feedstocks, and preferred end products. Our chipper conversion package allows operators to easily switch between grinding and chipping applications, while the Rotochopper replaceable mount allows for easy replacement of grinder mounts, chipper mounts, and knives. Rotochopper chipper knives are also indexable—by flipping them, operators can utilize both sides of the knife, increasing the life span of the part and decreasing wear costs.

At Rotochopper, our mulch grinders and wood chip grinders are known for their superior particle size control, allowing operators to create a finished product in just one pass. This advantage provides consistency in your end product that is not possible with alternative solutions and streamlines efficiency throughout the resizing process.

As with all Rotochopper equipment, the factory direct service and support provided by our team of experts is invaluable to minimizing downtime, maximizing productivity, and ensuring continued success.