To safely disconnect a transport dolly from a Rotochopper Generation II transport dolly, start by parking on level ground and […]

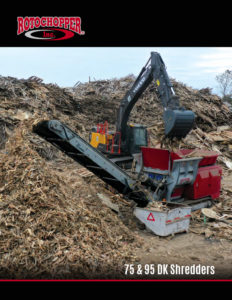

Learn More75 DK

Shredder

Shredding to the Extreme

The DK Shredder takes mobile shredding to the extreme with maximum output and full mobility. The combination of a powerful engine paired with a robust twin-rotor cutting system provides the efficiency and effectiveness you have been looking for in a shredder.

Contact a Sales Rep

Featured Specifications

Featuring simple operations through an intuitive touchscreen interface, the 75 DK Shredder is exceptionally reliable, easy to maintain and provides consistent output at a low rate of energy per ton of shredded material.

-

Advantages

Streamlined Operations

Shred contaminated materials and remove ferrous metal, then feed directly into your grinder to maximize operational efficiency and reduce downtime in one streamlined process.

Open Shredding Table

Twin rotor, open shredding table allows abrasive materials to pass freely, minimizing wear and increasing production rates.

Enhanced Feed Efficiency

Bi-directional shredding rotors ensure active shredding in both directions. The auto reverse threshold is easily adjusted to effectively match raw material consistency.

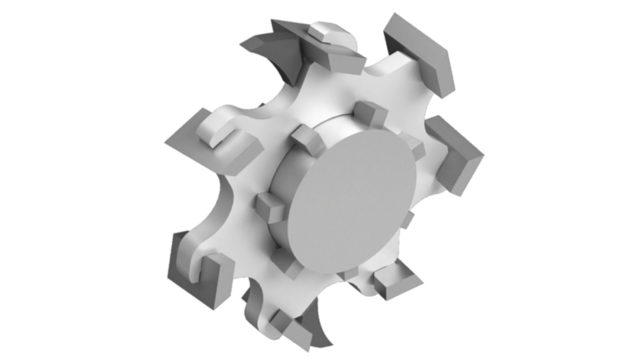

Versatile Rotors

Shredder adapts to your raw materials with the option of fine or rough rotor styles to create the output specifications you require.

Adjustable Discharge Height

Hydraulically adjustable discharge height provides options of shredding directly into a grinder, trailer, or bunker with ease.

Reduced Noise Emissions

Engineered design and low engine speed provide reduced noise emissions.

-

Exclusive Features

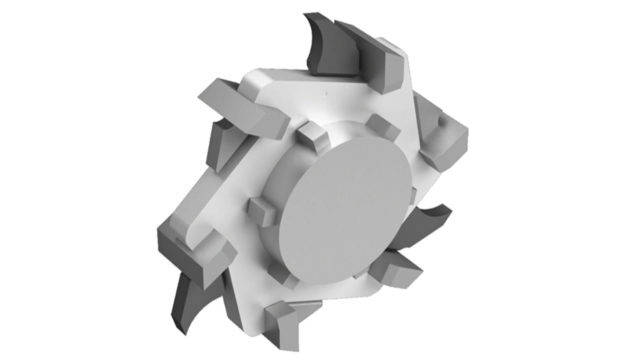

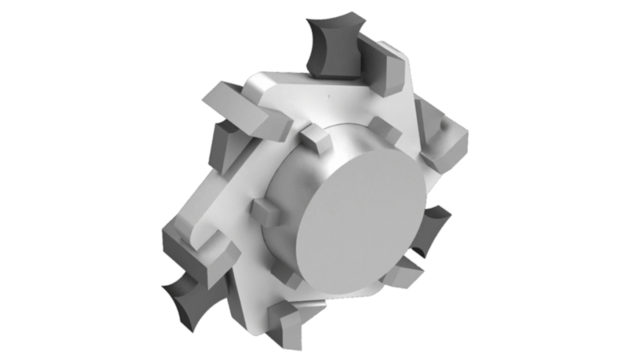

Twin Rotor Cutting System

Incredibly productive shredding system due to aggressive intake and synchronously running rotors. Maximum resistance provided with fully welded crushers, rippers, scrapers and breaker bar.

Double Tilting Hopper System

Large feeding area with double tilting hopper system provides optimal solution for material feeding to twin rotors.

Intuitive Controls

The shredder features simple operations and the ability to update parameter-settings through an intuitive touchscreen user interface and a remote control for convenient operation.

Hydrostatic Drives

Powerful hydrostatic drives deliver the torque you need for extreme duty applications and shredding efficiency.

Adjustable Cross Belt Magnet

Remove ferrous metal with optional integration of hydraulically adjustable cross belt magnet.

Robust Track Chassis

Hydraulic crawler tracks allow independent maneuvering of the machine and provides easy navigation options for difficult terrain.

-

Videos

Rotochopper DK Series Shredders

Since the addition of the 75 and 95 DK shredders, Rotochopper customers across the country are finding great success in a wide variety of use cases with their shredders. The DK series shredders boasts a powerful twin-rotor cutting system that is exceptionally reliable, easy to maintain and provides consistent output at a low rate of energy per ton of shredded material.

Subscribe to our YouTube Channel - Industries

-

Additional Specs

Dimensions

75 DK

- Length – 22’ 11” (7.0 m)

- Width – 8’ 8” (2.67 m)

- Height – 9’ 6” (2.9 m)

- Weight – 53,000 (24,040 kg)

Shredding Table

75 DK

- Table opening – 2’ 7” x 5’ (84 x 154 cm)

- Rotor lengths – 5’ 7” (175 cm)

- Rotor diameter – 2’ 1” (65 cm)

Options

- Choice of fine or rough rotors

- Hydraulically adjustable cross belt magnet

- Rubber pads for crawler tracks

- Dust suppression system with water source

The 75DK Shredder is also available as an electric model.

To learn more about this option – contact your sales representative.

Waste Wood Fine Rotors

- Patented cutting system utilizing a combination of cutting and crushing

- Cutting action for homogeneous output

- Crushing action for fewer superfine particles

- Aggressive automatic intake supports high throughput

Waste Wood Rough Rotors

- Crushing action for coarse primary shredding of wood waste

- Undeterred by non-shreddables such as iron fittings, screws and bolts

C & D/MSW Rotors

- Signature ripper combos provides aggressive material intake in both directions

- optimized configuration for automatic self-cleaning of the cutting unit

"The 75 DK Shredder is a total game changer. It makes the perfect chip for regrinding with our FP-66 and allows me to fill a 130-yard trailer in less than 20 minutes. I'm ecstatic!"

— Brad Bennett, Novem Waste

Additional Resources

How to Connect & Disconnect a Rotochopper Generation II Transport Dolly from a Tow Vehicle

This Rotochopper University Instruction Guide outlines the steps for connecting and disconnecting a transport dolly from a tow vehicle. […]

Learn MoreRotochopper Welcomes Mike Elling as Chief Financial Officer

We are delighted to announce the addition of Mike Elling to the Rotochopper team as Chief Financial Officer (CFO). In […]

Learn More