In the waste reduction industry, there are few things more important than maximizing productivity and output. Every minute of downtime—whether due to breakdowns, repairs, or other unforeseen circumstances—cuts into your operation’s uptime and, in turn, your profits. For grinding operations, regular maintenance plays a critical role in ensuring your machinery remains safe, productive, and profitable—even as you process abrasive feedstocks that wear on grinding components.

A comprehensive preventative maintenance package is the best way to keep your horizontal grinder running smoothly long-term. Partnering with a company that leverages the expertise of their technicians can ensure your operations identifies and addresses potential problems before they result in lost productivity and costly repairs.

The Importance of Proactive Maintenance

Preventative maintenance programs help minimize downtime and maintain operational efficiency through a combination of regularly scheduled maintenance checks and personalized recommendations on how to boost productivity. During a typical visit, maintenance technicians closely examine a grinder’s inner workings, including teeth, rotors, and hydraulic pumps. If any components are worn out or damaged, maintenance technicians can repair or replace them before they fail mid-production and disrupt the flow of work.

By monitoring grinding equipment and performing necessary repairs quickly, planned maintenance maximizes uptime and reduces a grinder’s lifetime maintenance cost, ultimately reducing the total cost of ownership for the significant majority of equipment. In addition to lower maintenance costs, regular preventative maintenance also extends the lifespan of the equipment—in some cases, by up to several years—and reduces equipment costs by as much as 18% to keep operations profitable even as machinery ages.

Minimizing Downtime with Rotochopper’s Preventative Maintenance Program

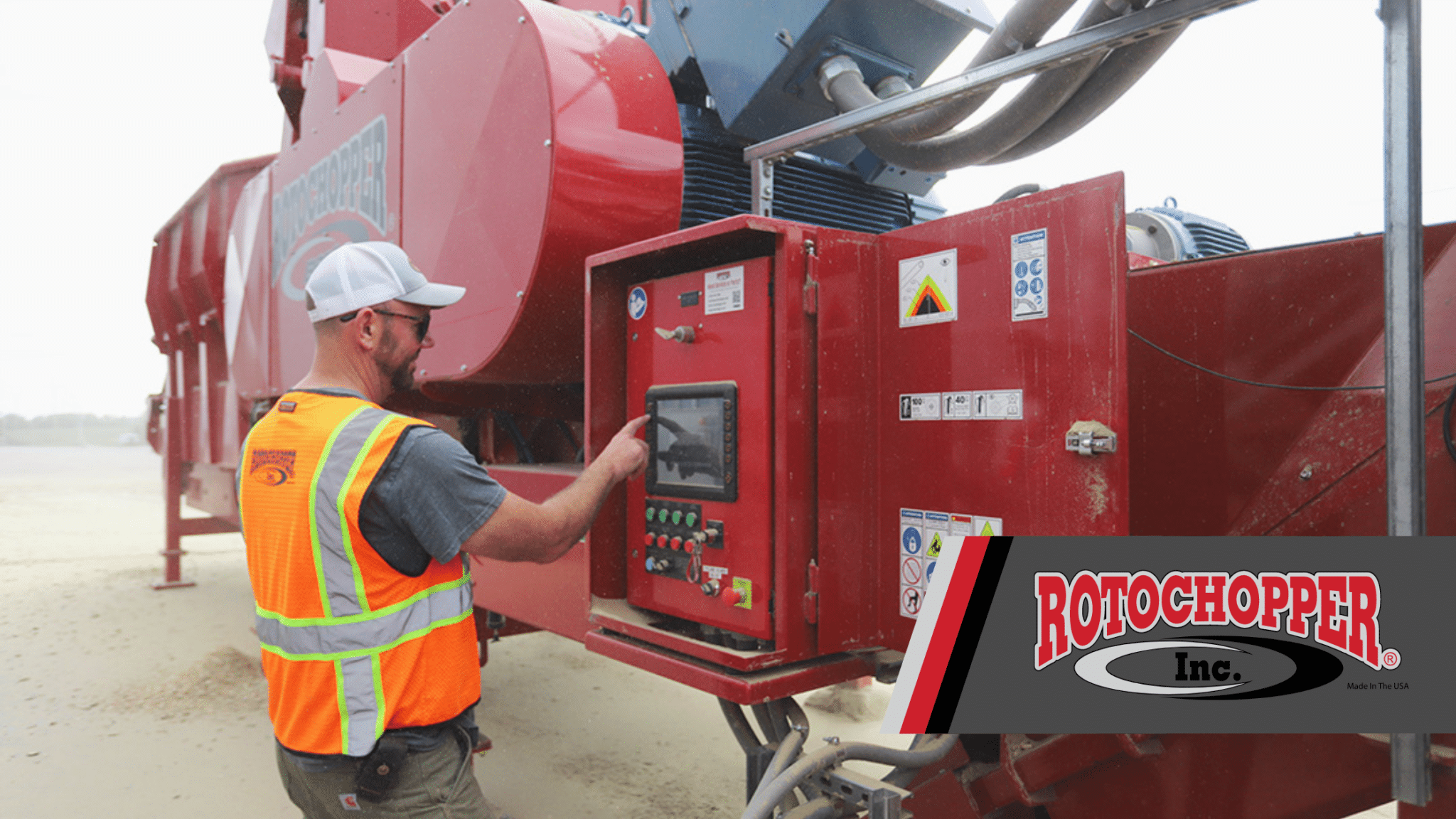

Rotochopper is proud to provide our customers with one of the most thorough and detail-oriented planned maintenance programs in the country. As a factory-direct manufacturer, our maintenance technicians have an unparalleled understanding of our equipment—from the optimal rotor placement to the ideal amp draw. To minimize the impact on production, our technicians conduct maintenance checks outside of peak operating hours and can even make one-off trips to perform emergency maintenance.

The factory-direct difference doesn’t end there. Our service technicians are expertly trained to inspect your grinder with respect to usage, maintenance history, performance, and the primary feedstocks of your operation. Because they have a deep understanding of Rotochopper equipment, our team can even recommend operational changes to better capitalize on our equipment’s strengths, such as pre-processing abrasive feedstocks with an industrial shredder.

Save Time with Rotochopper Planned Maintenance

Partnering with Rotochopper means horizontal grinder owners can further maximize their operation’s efficiency. With a factory-direct product specialist trained specifically to maintain Rotochopper equipment, operators ensure their machinery receives prompt and expert service.

Not only does planned maintenance minimize downtime—it saves operations money and time by reducing the need for an in-house mechanic, which is especially beneficial during labor shortages or when hiring a full-time mechanic isn’t feasible. With less time spent on routine maintenance, business owners can focus on their core operations without sacrificing efficiency.

With the Rotochopper team at the helm, operations can boost profitability and efficiency while decreasing costs, extending the life of their equipment, and increasing the trade-in value of their machinery.

Manage Preventative Maintenance with RotoLink®

Rotochopper’s proprietary RotoLink remote monitoring system allows grinder operators to analyze critical data, including operating temperature, vibration levels, and engine data, in real-time. Using this data, operations can keep tabs on equipment inefficiencies and track wear on critical parts, allowing them to order replacements ahead of time and pre-plan preventative maintenance when it’s most convenient. For troubleshooting operational issues, a live Rotochopper service expert is available remotely at the touch of a button.

Partner with an Experienced Grinder Manufacturer

At Rotochopper, we believe in helping our customers get the most out of their equipment—even after it leaves our lot. When you purchase a Rotochopper horizontal grinder, you do so knowing that our expert maintenance team is ready to assist with all your service concerns.

Contact a Rotochopper expert today, or learn more about our preventative maintenance program here.